Eaton : EU5C-SWD-EIP-MODTCP

153163 EU5C-SWD-EIP-MODTCP

EU5C-SWD-EIP-MODTCP /153163

Ağ Geçidi, SmartWire-DT, EthernetIP/MODBUS'ta 99 SWD kartı Fieldbus'a bağlantı ve SmartWire-DT kartı ve şalt cihazlarının beslenmesi için SmartWire-DT ağ geçidi. Ethernet IP veya MODBUS-TCP'ye bağlantı, Slave olarak entegre Ethernet anahtarı (10/100MBit) aracılığıyla gerçekleştirilir. IP adresinin ayarlanması bir DIP anahtarı veya DHCP kullanılarak gerçekleştirilir. 99'a kadar SmartWire-DT kartı bağlanabilir. Ağ geçidi ayrı bir teşhis arayüzü ile donatılmıştır.

Ağ Geçidi, SmartWire-DT, EthernetIP/MODBUS'ta 99 SWD kartı

Fieldbus'a bağlantı ve SmartWire-DT kartı ve şalt cihazlarının beslenmesi için SmartWire-DT ağ geçidi. Ethernet IP veya MODBUS-TCP'ye bağlantı, Slave olarak entegre Ethernet anahtarı (10/100MBit) aracılığıyla gerçekleştirilir. IP adresinin ayarlanması bir DIP anahtarı veya DHCP kullanılarak gerçekleştirilir. 99'a kadar SmartWire-DT kartı bağlanabilir. Ağ geçidi ayrı bir teşhis arayüzü ile donatılmıştır.

| Product range | SmartWire-DT coordinators |

| Function | For connection to the Ethernet-IP/MODBUS-TCP field bus |

| Short Description | Used to connect the SmartWire-DT communication system to industrial field bus systems. Powers SmartWire-DT modules and switchgear |

| Description | SmartWire-DT gateway for connecting up to 99 SmartWire-DT modules to an Industrial Ethernet network and for powering the SmartWire-DT modules and switchgear. The connection to an Ethernet IP or MODBUS-TCP is carried out via the integrated Ethernet switch (10/100 Mbit) as slave. Setting of the IP address is carried out using a DIP switch or DHCP. The gateway is equipped with a separate serial diagnostics interface (RJ45). |

| Accessories | Connection of up to 99 SWD slaves |

| Standards | IEC/EN 61131-2 EN 50178 |

| Approvals >Approvals |

UL CSA |

| Approvals >shipping classification |

DNV GL BV LRS |

| Approvals | |

| Dimensions (W x H x D) | 35 x 90 x 124 mm |

| Weight | 0.17 kg |

| Mounting | Top-hat rail IEC/EN 60715, 35 mm or screw fixing using fixing brackets ZB4-101-GF1 (accessories) |

| Mounting position | As required |

| Protection type (IEC/EN 60529, EN50178, VBG 4) | IP20 |

| Vibrations (IEC/EN 61131-2:2008) >Constant amplitude 3,5 mm |

5 - 8.4 Hz |

| Vibrations (IEC/EN 61131-2:2008) >Constant acceleration 1 g |

8.4 - 150 Hz |

| Mechanical shock resistance (IEC/EN 60068-2-27) semi-sinusoidal 15 g/11 ms | 9 Impacts |

| Drop to IEC/EN 60068-2-31 [Drop height] | 50 mm |

| Free fall, packaged (IEC/EN 60068-2-32) | 0.3 m |

| Overvoltage category | II |

| Pollution degree | 2 |

| Electrostatic discharge (IEC/EN 61131-2:2008) >Air discharge (Level 3) |

8 kV |

| Electrostatic discharge (IEC/EN 61131-2:2008) >Contact discharge (Level 2) |

4 kV |

| Electromagnetic fields (IEC/EN 61131-2:2008) >80 - 1000 MHz |

10 V/m |

| Electromagnetic fields (IEC/EN 61131-2:2008) >1.4 - 2 GHz |

3 V/m |

| Electromagnetic fields (IEC/EN 61131-2:2008) >2 - 2.7 GHz |

1 V/m |

| Radio interference suppression | EN 55011 Class A |

| Burst (IEC/EN 61131-2:2008, Level 3) >Supply cable |

2 kV |

| Burst (IEC/EN 61131-2:2008, Level 3) >Fieldbus cable |

1 kV |

| Burst (IEC/EN 61131-2:2008, Level 3) >SmartWire-DT cable |

1 kV |

| Surge (IEC/EN 61131-2:2008, Level 1) >Supply cable |

0.5 kV |

| Radiated RFI (IEC/EN 61131-2:2008, Level 3) | 10 V |

| Climatic environmental conditions >Climatic proofing |

In accordance with IEC 60068-2 |

| Climatic environmental conditions >Ambient temperature >Operation [ϑ] |

-25 - +55 °C |

| Climatic environmental conditions >Ambient temperature >Storage [ϑ] |

-40 - +70 °C |

| Atmospheric conditions

>Relative humidity, non-condensing (IEC/EN 60068-2-30) |

5 - 95 % |

| Atmospheric conditions

>Air pressure (operation) |

795 - 1080 hPa |

| Rated operational voltage [UAux] | 24 V DC (-15/+20%) V |

| Residual ripple on the input voltage | ≦ 5 % |

| Protection against polarity reversal | Yes |

| Max. current [Imax] | 3 A |

| Short-circuit rating | no, external fuse FAZ Z3 |

| Power loss [P] | Normally 1 W |

| Potential isolation | No |

| Rated operating voltage of 24-V-DC slaves | typ. UAux - 0.2 V |

| Supply voltage [UPow] | 24 V DC (-15/+20%) V |

| Input voltage ripple | ≦ 5 % |

| Siemens MPI, (optional) | yes |

| Rated current [I] | 0.7 A |

| Overload proof | yes |

| Inrush current and duration | 12.5 A/6 ms A |

| Heat dissipation at 24 V DC | 3.8 W |

| Potential isolation between UPow and 15 V SmartWire-DT supply voltage | No |

| Bridging voltage dips | 10 ms |

| Repetition rate | 1 s |

| Status indication | yes LED |

| Rated operating voltage [Ue] | 14,5 ± 3 % V |

| max. current [Imax] | 0.7 A |

| Short-circuit rating | Yes |

| Connection type | Push in terminals |

| Solid | 0.2 - 1.5 mm2 |

| Flexible with ferrule | 0.25 - 1.5 mm2 |

| UL/CSA solid or stranded | 24 - 16 AWG |

| Station type | SmartWire-DT master |

| Number of SmartWire-DT slaves | 99 |

| Baud Rates | 125 250 kBd |

| Status indication | SmartWire-DT master LED: red/green Configurations LED: red/green LED |

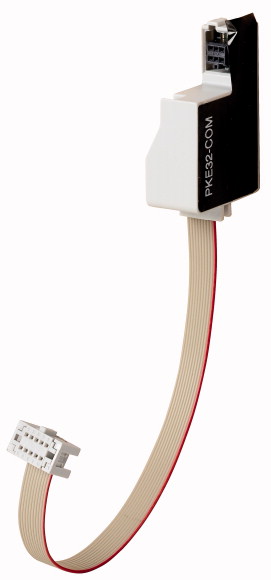

| Connections | Plug, 8-pole |

| Plug connectors | Blade terminal SWD4-8MF2 |

| Module type | Ethernet IP/MODBUS-TCP Slave |

| Protocol | Ethernet IP/MODBUS-TCP |

| Input data, max. | Ethernet-IP: 546 MODBUS-TCP: 800 Byte |

| Output data, max. | Ethernet-IP: 496 MODBUS-TCP: 642 Byte |

| Baud Rate >Baud Rates |

10/100 MBit/s |

| Baud Rate >Baud rate setting |

automatic |

| Station address | IP |

| Address allocation | viaDip switch/DHCP/BOOTP |

| Status display interface [Multi colour] | MS, Link status LED |

| Connection design for field bus | 2 x RJ45 (2-channel switch) |

| Potential isolation | Yes |

| Other technical data (sheet catalogue) | Technical data |

| Notes | If contactors with a total current consumption > 3 A are connected, a power feeder module EU5C-SWD-PF1/2 has to be used. If SWD modules with a total current consumption > 0.7 A are connected, a power feeder module EU5C-SWD-PF2 has to be used. |

| Rated operational current for specified heat dissipation [In] | 0 A |

| Heat dissipation per pole, current-dependent [Pvid] | 0 W |

| Equipment heat dissipation, current-dependent [Pvid] | 0 W |

| Static heat dissipation, non-current-dependent [Pvs] | 1 W |

| Heat dissipation capacity [Pdiss] | 0 W |

| Operating ambient temperature min. | -25 °C |

| Operating ambient temperature max. | +55 °C |

| Degree of Protection | IP20 |

| 10.2 Strength of materials and parts >10.2.2 Corrosion resistance |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.1 Verification of thermal stability of enclosures |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.2 Verification of resistance of insulating materials to normal heat |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.4 Resistance to ultra-violet (UV) radiation |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.5 Lifting |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.2 Strength of materials and parts >10.2.6 Mechanical impact |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.2 Strength of materials and parts >10.2.7 Inscriptions |

Meets the product standard´s requirements. |

| 10.3 Degree of protection of ASSEMBLIES | Meets the product standard´s requirements. |

| 10.4 Clearances and creepage distances | Meets the product standard´s requirements. |

| 10.5 Protection against electric shock | Does not apply, since the entire switchgear needs to be evaluated. |

| 10.6 Incorporation of switching devices and components | Does not apply, since the entire switchgear needs to be evaluated. |

| 10.7 Internal electrical circuits and connections | Is the panel builder´s responsibility. |

| 10.8 Connections for external conductors | Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.2 Power-frequency electric strength |

Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.3 Impulse withstand voltage |

Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.4 Testing of enclosures made of insulating material |

Is the panel builder´s responsibility. |

| 10.10 Temperature rise | The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| 10.11 Short-circuit rating | Is the panel builder´s responsibility. |

| 10.12 Electromagnetic compatibility | Is the panel builder´s responsibility. |

| 10.13 Mechanical function | The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| Supply voltage AC 50 Hz | 0 - 0 V |

| Supply voltage AC 60 Hz | 0 - 0 V |

| Supply voltage DC | 20.4 - 28.8 V |

| Voltage type of supply voltage | DC |

| Supporting protocol for TCP/IP | No |

| Supporting protocol for PROFIBUS | No |

| Supporting protocol for CAN | No |

| Supporting protocol for INTERBUS | No |

| Supporting protocol for ASI | No |

| Supporting protocol for KNX | No |

| Supporting protocol for MODBUS | Yes |

| Supporting protocol for Data-Highway | No |

| Supporting protocol for DeviceNet | No |

| Supporting protocol for SUCONET | No |

| Supporting protocol for LON | No |

| Supporting protocol for SERCOS | No |

| Supporting protocol for PROFINET IO | No |

| Supporting protocol for PROFINET CBA | No |

| Supporting protocol for Foundation Fieldbus | No |

| Supporting protocol for EtherNet/IP | No |

| Supporting protocol for AS-Interface Safety at Work | No |

| Supporting protocol for DeviceNet Safety | No |

| Supporting protocol for INTERBUS-Safety | No |

| Supporting protocol for PROFIsafe | No |

| Supporting protocol for SafetyBUS p | No |

| Supporting protocol for other bus systems | No |

| Radio standard Bluetooth | No |

| Radio standard WLAN 802.11 | No |

| Radio standard GPRS | No |

| Radio standard GSM | No |

| Radio standard UMTS | No |

| IO link master | No |

| System accessory | Yes |

| Degree of protection (IP) | IP20 |

| With potential separation | No |

| Fieldbus connection over separate bus coupler possible | No |

| Rail mounting possible | Yes |

| Wall mounting/direct mounting | Yes |

| Front build in possible | No |

| Rack-assembly possible | No |

| Suitable for safety functions | Yes |

| Category according to EN 954-1 | |

| SIL according to IEC 61508 | None |

| Performance level acc. EN ISO 13849-1 | None |

| Appendant operation agent (Ex ia) | No |

| Appendant operation agent (Ex ib) | No |

| Explosion safety category for gas | None |

| Explosion safety category for dust | None |

| Width | 35 mm |

| Height | 90 mm |

| Depth | 122 mm |

| UL File No. | E29184 |

| UL Category Control No. | NKCR |

| CSA File No. | 2324643 |

| CSA Class No. | 3211-07 |

| North America Certification | UL listed, CSA certified |

| Specially designed for North America | No |

Tüm ürünlerimiz, zorlu çalışma koşullarında dahi maksimum güvenilirlik sunar ve işletmenizin operasyonlarını sorunsuz şekilde sürdürmesine yardımcı olur. Endüstriyel otomasyon, enerji yönetimi, kablolama çözümleri ve daha birçok alanda sunduğumuz ürünler, farklı sektörlerdeki ihtiyaçlara esneklikle uyum sağlar.

Ayrıca, ürünlerimiz sadece kaliteli malzemelerle üretilmiş olup, uluslararası standartlara uygunluk göstermektedir. Müşterilerimize sunduğumuz çözümlerle, operasyonel verimliliklerini artırmalarına ve maliyetlerini optimize etmelerine olanak tanıyoruz. Teknolojik gelişmeleri yakından takip eden firmamız, sürekli olarak yenilikçi ürünler sunarak, müşterilerimizin rekabet avantajı elde etmesine destek vermektedir.

Her bir ürün sayfamızda, teknik detaylar, kullanım alanları ve ürün özelliklerine dair kapsamlı bilgilere ulaşabilirsiniz. Endüstriyel süreçlerinizi güçlendirmek için ihtiyacınız olan tüm ürünleri sitemizden keşfedebilir, sorunsuz bir satın alma deneyimi yaşayabilirsiniz.

Benzer Ürünler

Aradığınız ürünü bulamıyor musunuz?

SİZE YARDIMCI OLALIM

Aradığınız Ürünü Bulamadınız mı? Bize Bildirin, Sizin İçin Tedarik Edelim!

Web sitemizde yer almayan ya da stokta bulunmayan ürünleri mi arıyorsunuz? İhtiyacınızı bize bildirin, uzman ekibimiz en kısa sürede sizinle iletişime geçerek size en uygun çözümü bulsun.