Industrial Solutions

Prepare for the Future

Today!

Smart Robotic Systems

A New Era of Efficiency

Solution-Oriented

Our Applications

At Mnelko, our project implementation solutions are meticulously designed to simplify your business processes and boost your efficiency. These solutions are developed to enhance your company's performance and increase its competitive edge by offering effective implementation support at every stage of your projects.

Show all applicationsMetal Processing Automation Solutions

Textile Automation Solutions

Food Production and Packaging Automation Solutions

Marble Processing Automation Solutions

Wood Processing Automation Solutions

Crane Automation Solutions

Update Your

Technology

Leveraging our expertise in industrial automation, we revise the old machines used in your factory and adapt them to modern standards, ensuring your production processes operate more efficiently and reliably.

Reggiani Textile Printing Machine Revision

We subject Reggiani textile printing machines to a detailed revision process, enhancing their performance and restoring them to your production line.

Monforts Textile Ram Machine Revision

We meticulously renew Monforts ram machines, bringing them up to production standards for high efficiency and long-lasting use.

Babcock Textile Ram Machine Revision

Through our revision processes on Babcock ram machines, we not only increase energy efficiency but also ensure the machine regains its original operational precision.

Arioli Textile Fixing – Steaming Machine Revision

We comprehensively overhaul Arioli fixing and steaming machines to improve process quality and achieve maximum efficiency in textile production.

Reduce Your Costs

Through Revision

Frequently Asked Questions

Now is the Perfect Time to Learn More About Machine Revision

It is now possible to enhance the performance of old machines, ensure production continuity, and reduce maintenance costs. Through the revision process, your machines regain their original precision and your production line gains strength.

Discover our machine revision solutions to boost your production efficiency and save on investment costs. We offer tailored revision services for every brand and model.

1 - What is machine revision?

Machine revision is the process of renewing the mechanical, electrical, and automation systems of aging or underperforming machines. This process allows the machine to regain the operational efficiency and safety it had on its first day.

2 - Is revision more advantageous than purchasing new machines?

In most cases, revision is a much more economical solution compared to buying new machines. When properly implemented, it not only saves costs but also modernizes your production line without causing any interruptions.

3 - Which machines can be revised?

We offer revision services for a wide range of machines used in the textile sector, including various brands and models such as Reggiani, Monforts, Babcock, Arioli, and Mezzera. Depending on the needs, all systems can be renewed either partially or entirely.

4 - How long does the revision process take?

The duration of the revision process depends on the type, current condition, and scope of the machine. It is generally completed within a few weeks. Throughout the process, transparent communication is maintained and the plan is strictly followed

5 - Do you provide technical support after revision?

Yes. We offer technical support and maintenance services under warranty for the machines we revise. Additionally, we support post-process production efficiency through operator training.

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.

IN EVERY FIELD OF THE INDUSTRY

Where Technology Meets Experience...

We are a supplier of the necessary products for industrial automation applications and a provider of engineering services related to these products, serving a worldwide customer base that focuses on end users.

Wide Product Diversity

With our extensive supplier network, Mnelko provides access to over 500,000 product varieties from a single source, empowering businesses to fully meet their automation and control system needs.

Technical Expertise

Our technical experts, both at our headquarters and available for on-site visits at your facility, help select the most appropriate products for your applications or organize training sessions for your employees, thereby reducing unplanned downtimes, saving energy, and enhancing your production quality.

Mnelko Blog

Recent News

Smart Manufacturing with Delta Robotics: Power of Articulated & SCARA Robot Arms

Discover Delta Electronics’ 6-axis articulated robot series and versatile SCARA robot arms—offering speed, precision, and integrated automation solutions.

Read more

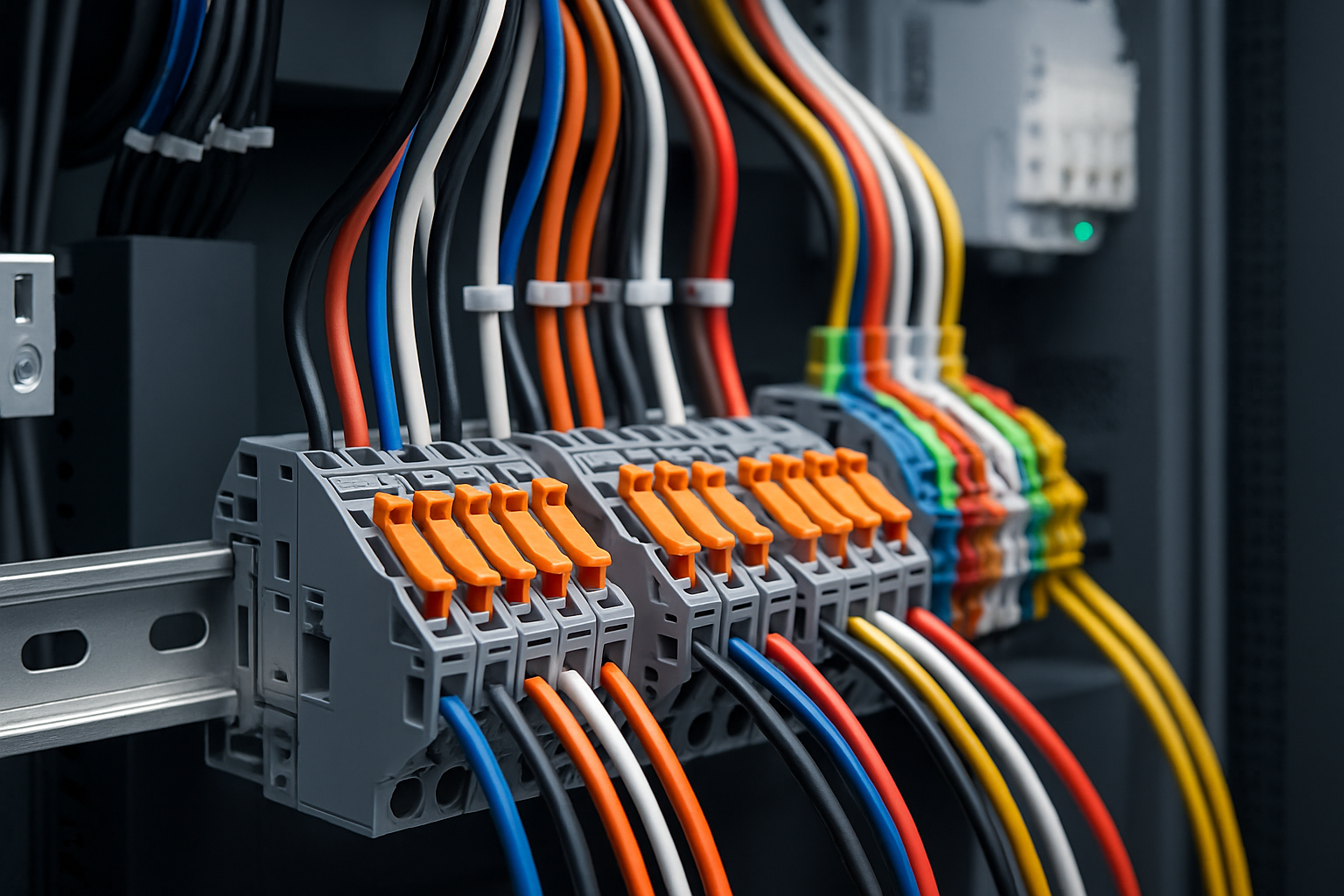

Reliable and Practical Industrial Automation Solutions with WAGO Spring Connection Systems

Discover fast, safe, and durable solutions in your automation projects with WAGO’s spring connection technology. We’ve listed the most preferred products.

Read more