Eaton : EU1H-SWD-1XD-1

191089 EU1H-SWD-1XD-1

EU1H-SWD-1XD-1 /191089

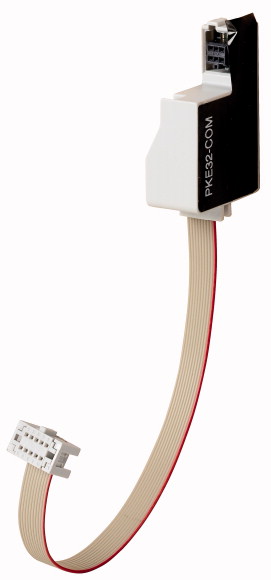

2 yollu hidrolik valf için SWD modülü IP65 DIN EN 175301-803'e uygun bağlantıyla hidrolik anahtar valfinin bağlantısı için IP65 koruma kategorisindeki SmartWire-DT cihazları, otomatik adres ayarı, 24 V DC 1,6/1,3 A (60/70 °C) dijital çıkış ve kısa devre koruması

2 yollu hidrolik valf için SWD modülü IP65

DIN EN 175301-803'e uygun bağlantıyla hidrolik anahtar valfinin bağlantısı için IP65 koruma kategorisindeki SmartWire-DT cihazları, otomatik adres ayarı, 24 V DC 1,6/1,3 A (60/70 °C) dijital çıkış ve kısa devre koruması

| Product range | SmartWire-DT slave |

| Basic function | Digital modules |

| Function | For connecting digital 2-way switching valves |

| Short Description | with supply |

| Connection to SmartWire-DT | yes |

| Standards | IEC/EN 61131-2 EN 50178_x |

| Approvals >Approvals |

UL |

| Dimensions (W x H x D) | 44.7 x 77.4 x 51.9 mm |

| Weight | 0.08 kg |

| Mounting | Can be screwed onto valve connector in conformity with DIN EN 175301-803 |

| Mounting position | As required |

| Power supply >Power loss [P] |

1.8 W |

| Air pressure (operation) | 795 - 1080 hPa |

| Ambient temperature >Operation [ϑ] |

-25 - +70 (observe derating) °C |

| Ambient temperature >Storage / Transport [ϑ] |

-40 - +85 °C |

| Relative humidity >Condensation |

permissible |

| Relative humidity >Relative humidity, non-condensing (IEC/EN 60068-2-30) |

5 - 95 % |

| Protection type (IEC/EN 60529, EN50178, VBG 4) | IP65 |

| Vibrations (IEC/EN 61131-2:2008) >Constant amplitude 3,5 mm |

5 - 8.4 Hz |

| Vibrations (IEC/EN 61131-2:2008) >Constant acceleration 1 g |

8.4 - 150 Hz |

| Mechanical shock resistance (IEC/EN 60068-2-27) semi-sinusoidal 30 g/11 ms | 9 Impacts |

| Drop to IEC/EN 60068-2-31 [Drop height] | 50 mm |

| Free fall, packaged (IEC/EN 60068-2-32) | 0.3 m |

| Overvoltage category | II |

| Pollution degree | 3 |

| Electrostatic discharge (IEC/EN 61131-2:2008) >Air discharge (Level 3) |

8 kV |

| Electrostatic discharge (IEC/EN 61131-2:2008) >Contact discharge (Level 2) |

4 kV |

| Electromagnetic fields (IEC/EN 61131-2:2008) >80 - 1000 MHz |

10 V/m |

| Electromagnetic fields (IEC/EN 61131-2:2008) >1.4 - 2 GHz |

3 V/m |

| Electromagnetic fields (IEC/EN 61131-2:2008) >2 - 2.7 GHz |

1 V/m |

| Radio interference suppression (SmartWire-DT) | EN 55011 Class A |

| Burst (IEC/EN 61131-2:2008, Level 3) >Supply cable |

2 kV |

| Burst (IEC/EN 61131-2:2008, Level 3) >SmartWire-DT cables |

1 kV |

| Surge (IEC/EN 61131-2:2008, Level 1) >Surge power cables |

1 kV |

| Radiated RFI (IEC/EN 61131-2:2008, Level 3) | 10 V |

| Station type | SmartWire-DT slave |

| Setting the baud rate | automatic |

| Baud rate (data transfer speed) | maximum125/250/500/1000/2000 kbps |

| Status SmartWire-DT | Green LED |

| SWD-IN | M12 plug (A-keyed), 5 pole |

| SWD-OUT | M12 plug (A-keyed), 5 pole |

| Current consumption (24V, without sensor and without I/O supply) >Current consumption (24 V SWD supply) |

45 mA |

| Sensor supply >Overload and short-circuit proof |

yes, with diagnostics |

| Terminal for I/O sensor >Connection type |

Valve connector DIN EN 175301-803 |

| Quantity | 1 |

| Output current | 1.6 (at 60°C), 1.3 (at 70°C) A |

| Overload proof | yes, with diagnostics |

| Maximum switching frequency | 1 Hz |

| Status display outputs | yellow LED |

| Rated operational voltage [UAux] | 24 V DC (-15/+20%) V |

| Permissible range | 20.4 - 28.8 V DC |

| Siemens MPI, (optional) | yes |

| Short-circuit rating | Not relevant |

| Potential isolation | Galvanically isolated from the SmartWire-DT network |

| Outputs to SmartWire-DT | Yes |

| Rated operational current for specified heat dissipation [In] | 1.6 A |

| Equipment heat dissipation, current-dependent [Pvid] | 0.5 W |

| Static heat dissipation, non-current-dependent [Pvs] | 1.3 W |

| Operating ambient temperature min. | -25 °C |

| Operating ambient temperature max. | +70 °C |

| Degree of Protection | IP65 |

| 10.2 Strength of materials and parts >10.2.2 Corrosion resistance |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.1 Verification of thermal stability of enclosures |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.2 Verification of resistance of insulating materials to normal heat |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.4 Resistance to ultra-violet (UV) radiation |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.5 Lifting |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.2 Strength of materials and parts >10.2.6 Mechanical impact |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.2 Strength of materials and parts >10.2.7 Inscriptions |

Meets the product standard´s requirements. |

| 10.3 Degree of protection of ASSEMBLIES | Meets the product standard´s requirements. |

| 10.4 Clearances and creepage distances | Meets the product standard´s requirements. |

| 10.5 Protection against electric shock | Does not apply, since the entire switchgear needs to be evaluated. |

| 10.6 Incorporation of switching devices and components | Does not apply, since the entire switchgear needs to be evaluated. |

| 10.7 Internal electrical circuits and connections | Is the panel builder´s responsibility. |

| 10.8 Connections for external conductors | Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.2 Power-frequency electric strength |

Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.3 Impulse withstand voltage |

Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.4 Testing of enclosures made of insulating material |

Is the panel builder´s responsibility. |

| 10.10 Temperature rise | The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| 10.11 Short-circuit rating | Is the panel builder´s responsibility. |

| 10.12 Electromagnetic compatibility | Is the panel builder´s responsibility. |

| 10.13 Mechanical function | The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| UL File No. | E205091 |

| North America Certification | UL listed |

| Specially designed for North America | No |

Mnelko olarak, endüstriyel otomasyon çözümlerinde güvenilir bir iş ortağı olarak, geniş ürün yelpazesi ile işletmenizin tüm ihtiyaçlarını karşılamaya yönelik kaliteli ve yenilikçi ürünler sunmaktayız. Ürün portföyümüz, modern endüstriyel süreçleri desteklemek amacıyla yüksek performans, dayanıklılık ve verimlilik ilkeleri doğrultusunda tasarlanmış çözümlerden oluşur.

Tüm ürünlerimiz, zorlu çalışma koşullarında dahi maksimum güvenilirlik sunar ve işletmenizin operasyonlarını sorunsuz şekilde sürdürmesine yardımcı olur. Endüstriyel otomasyon, enerji yönetimi, kablolama çözümleri ve daha birçok alanda sunduğumuz ürünler, farklı sektörlerdeki ihtiyaçlara esneklikle uyum sağlar.

Ayrıca, ürünlerimiz sadece kaliteli malzemelerle üretilmiş olup, uluslararası standartlara uygunluk göstermektedir. Müşterilerimize sunduğumuz çözümlerle, operasyonel verimliliklerini artırmalarına ve maliyetlerini optimize etmelerine olanak tanıyoruz. Teknolojik gelişmeleri yakından takip eden firmamız, sürekli olarak yenilikçi ürünler sunarak, müşterilerimizin rekabet avantajı elde etmesine destek vermektedir.

Her bir ürün sayfamızda, teknik detaylar, kullanım alanları ve ürün özelliklerine dair kapsamlı bilgilere ulaşabilirsiniz. Endüstriyel süreçlerinizi güçlendirmek için ihtiyacınız olan tüm ürünleri sitemizden keşfedebilir, sorunsuz bir satın alma deneyimi yaşayabilirsiniz.

Tüm ürünlerimiz, zorlu çalışma koşullarında dahi maksimum güvenilirlik sunar ve işletmenizin operasyonlarını sorunsuz şekilde sürdürmesine yardımcı olur. Endüstriyel otomasyon, enerji yönetimi, kablolama çözümleri ve daha birçok alanda sunduğumuz ürünler, farklı sektörlerdeki ihtiyaçlara esneklikle uyum sağlar.

Ayrıca, ürünlerimiz sadece kaliteli malzemelerle üretilmiş olup, uluslararası standartlara uygunluk göstermektedir. Müşterilerimize sunduğumuz çözümlerle, operasyonel verimliliklerini artırmalarına ve maliyetlerini optimize etmelerine olanak tanıyoruz. Teknolojik gelişmeleri yakından takip eden firmamız, sürekli olarak yenilikçi ürünler sunarak, müşterilerimizin rekabet avantajı elde etmesine destek vermektedir.

Her bir ürün sayfamızda, teknik detaylar, kullanım alanları ve ürün özelliklerine dair kapsamlı bilgilere ulaşabilirsiniz. Endüstriyel süreçlerinizi güçlendirmek için ihtiyacınız olan tüm ürünleri sitemizden keşfedebilir, sorunsuz bir satın alma deneyimi yaşayabilirsiniz.

Benzer Ürünler

Aradığınız ürünü bulamıyor musunuz?

SİZE YARDIMCI OLALIM

Aradığınız Ürünü Bulamadınız mı? Bize Bildirin, Sizin İçin Tedarik Edelim!

Web sitemizde yer almayan ya da stokta bulunmayan ürünleri mi arıyorsunuz? İhtiyacınızı bize bildirin, uzman ekibimiz en kısa sürede sizinle iletişime geçerek size en uygun çözümü bulsun.