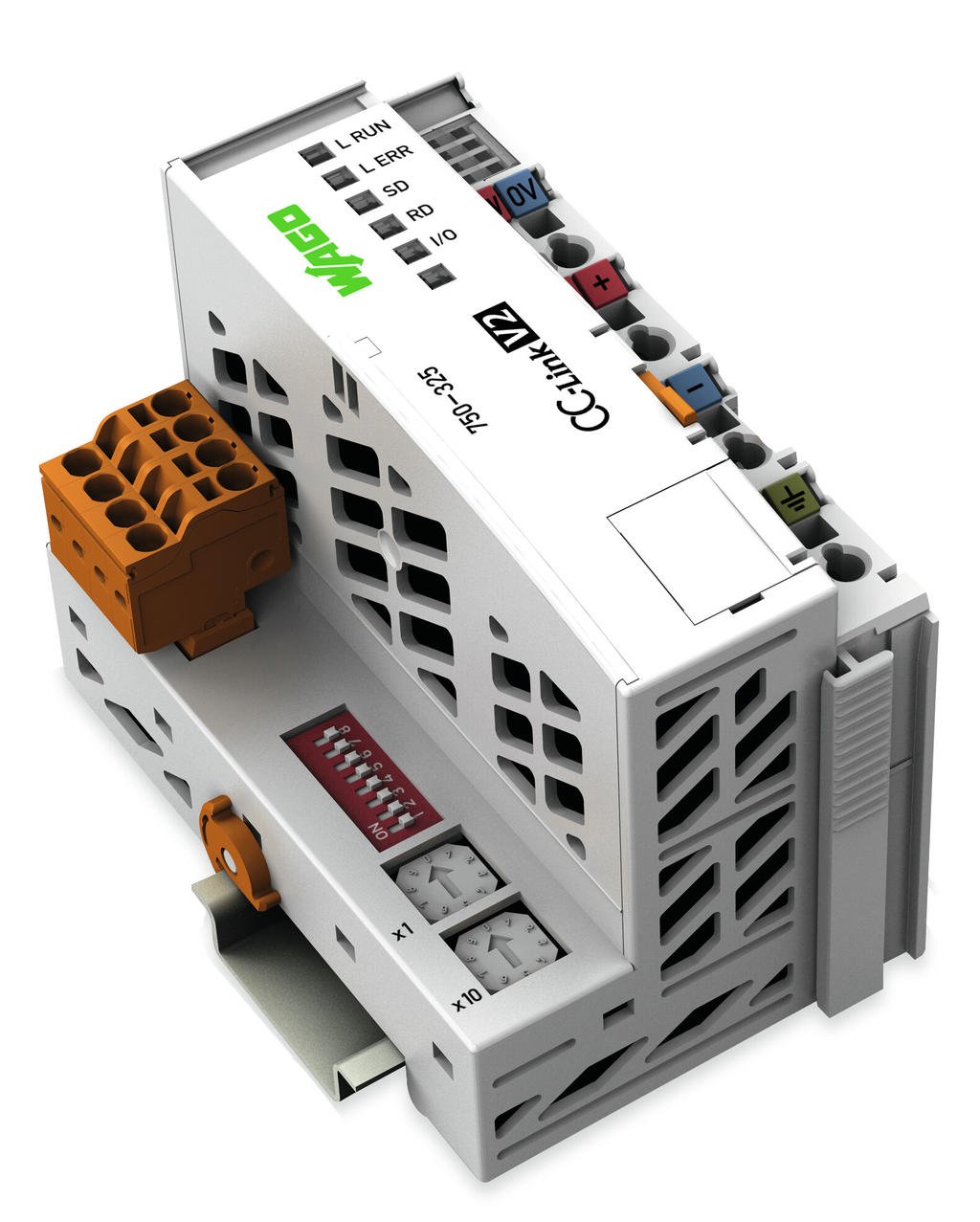

Wago : 750-325

Fieldbus Coupler CC-Link

750-325

Fieldbus Kuplörü CC-Link; açık gri This fieldbus coupler connects the WAGO‐I/O-SYSTEM as a slave to the CC-Link fieldbus. The fieldbus coupler supports the CC-Link protocol versions V1.1. and V2.0.The fieldbus coupler detects all connected I/O modules and creates a local process image. This process image may include a mixed arrangement of analog (word-by-word data transfer) and digital (bit-by-bit data transfer) modules.CC‐Link allows the storing of the process image in the corresponding Master control (PLC, PC or NC).The local process image is divided into two data zones containing the data received and the data to be sent. The process data can be sent via the CC-Link protocol to a control system for further processing. The process output data can be sent via the CC-Link protocol.The data of the analog modules is stored in the process image that is created automatically according to the order in which the modules are connected to the coupler.The bits of the digital modules are sent byte by byte and added to the analog data. If the amount of digital information exceeds eight bits, the buscoupler automatically starts with a new byte.

Fieldbus Kuplörü CC-Link; açık gri

This fieldbus coupler connects the WAGO‐I/O-SYSTEM as a slave to the CC-Link fieldbus. The fieldbus coupler supports the CC-Link protocol versions V1.1. and V2.0.

The fieldbus coupler detects all connected I/O modules and creates a local process image. This process image may include a mixed arrangement of analog (word-by-word data transfer) and digital (bit-by-bit data transfer) modules.

CC‐Link allows the storing of the process image in the corresponding Master control (PLC, PC or NC).

The local process image is divided into two data zones containing the data received and the data to be sent. The process data can be sent via the CC-Link protocol to a control system for further processing. The process output data can be sent via the CC-Link protocol.

The data of the analog modules is stored in the process image that is created automatically according to the order in which the modules are connected to the coupler.

The bits of the digital modules are sent byte by byte and added to the analog data. If the amount of digital information exceeds eight bits, the buscoupler automatically starts with a new byte.

| İletişim | CC-Link |

| Device-specific | Operation mode: CC-Link V2.0 (default setting)/V1.1; Extended cyclic setting: 1, 2, 4 (default setting), 8 cycles |

| Number of fieldbus nodes on the master max. | 64 |

| Baud rate | 156 kBd … 10 MBd |

| Fieldbus segment length max. | 1200 m |

| Transmission medium | Shielded Cu cable 2 / 3 x 0.5 mm² |

| İstasyon adresleri | 1 … 4 / 4 (default setting) |

| I/O modülü sayısı (düğüm başına) | 64 |

| Maks. giriş proses görüntüsü | RX (digital inputs): V1.1: 16, 48, 80, 112 bits; V2.0: 16, 48, 80, 112 bits (1 cycle); V2.0: 16, 80, 144, 208 bits (2 cycles); V2.0: 48, 176, 304, 432 bits (4 cycles); V2.0: 112, 368, 624, 880 bits (8 cycles) and 16 bits per system area; RWr (analog inputs): V1.1: 4, 8, 12, 16 words (16 bits); V2.0: 4, 8, 12, 16 words (1 cycle); V2.0: 8, 16, 24, 32 words (2 cycles); V2.0: 16, 32, 48, 64 words (4 cycles); V2.0: 32, 64, 96, 128 words (8 cycles) |

| Maks. çıkış proses görüntüsü | RY (digital outputs): V1.1: 16, 48, 80, 112 bits; V2.0: 16, 48, 80, 112 bits (1 cycle); V2.0: 16, 80, 144, 208 bits (2 cycles); V2.0: 48, 176, 304, 432 bits (4 cycles); V2.0: 112, 368, 624, 880 bits (8 cycles) and 16 bits per system area; RWw (analog outputs): V1.1: 4, 8, 12, 16 words (16 bits); V2.0: 4, 8, 12, 16 words (1 cycle); V2.0: 8, 16, 24, 32 words (2 cycles); V2.0: 16, 32, 48, 64 words (4 cycles); V2.0: 32, 64, 96, 128 words (8 cycles) |

| System supply voltage | DC 24 V(-25 … +30 %); via wiring level (CAGE CLAMP® connection) |

| Current consumption, system supply (5 V) | 200mA |

| Total current for system supply | 1.800mA |

| Field supply voltage | DC 24 V (-25 … +30 %); via power jumper contacts |

| Anma yükünde giriş akımı tip. (24 V) | 600mA |

| Nominal yükte güç kaynağı verimi (tip.) (24 V) | 90% |

| İzolasyon | 500 V sistem/besleme |

| Number of outgoing power jumper contacts | 3 |

| Current carrying capacity of the power jumper contacts | 10A |

| Connection technology: communication/fieldbus | CC-Link: 1 x 4-pole male connector |

| Connection technology: field supply | 6 x CAGE CLAMP® |

| Connection technology: system supply | 2 x CAGE CLAMP® |

| Connection technology: Device configuration | 1 x 4-pole male connector |

| Connection type (1) | System/field supply |

| Tek damarlı boylar | 0,08 … 2,5 mm² / 28 … 14 AWG |

| İnce bükümlü kablolar | 0,08 … 2,5 mm² / 28 … 14 AWG |

| Sıyırma uzunluğu | 8 … 9 mm / 0.31 … 0.35 inch |

| Width | 61,5 mm / 2.421 inch |

| Height | 71,9 mm / 2.831 inch |

| DIN rayın üst kenarından yükseklik | 64,7 mm / 2.547 inch |

| Depth | 100 mm / 3.937 inch |

| Montaj tipi | DIN 35 ray |

| Renk | açık gri |

| Gövde malzemesi | Polycarbonate, polyamide 6.6 |

| Ağırlık | 148,5 |

| Uygunluk işareti | CE |

| Surrounding air (operating) temperature | 0 … 55 °C |

| Surrounding air (storage) temperature | -40 … 85 °C |

| Koruma sınıfı | IP20 |

| Kirlilik derecesi (5) | 2 per IEC 61131-2 |

| Çalışma yüksekliği | 0 … 2000 m |

| Montaj pozisyonu | horizontal (standing/lying) or vertical |

| Nısbi nem (yoğuşmasız) | 95% |

| Titreşime dayanıklı | acc. to IEC 60068-2-6 |

| Darbe direnci | 15g per IEC 60068-2-27 |

| EMV-Störfestigkeit | acc. to EN 61000-6-2 |

| EMU: |

acc. to EN 61000-6-4 |

| Kirletici maddelere maruziyet | Per IEC 60068-2-42 and IEC 60068-2-43 |

| Permissible H2S contaminant concentration at a relative humidity |

10ppm |

| Permissible SO2 contaminant concentration at a relative humidity |

25ppm |

| SAP´den ambalaj tipi | BOX |

| Country of origin | DE |

| GTIN | 4055143597449 |

| Customs Tariff No. | 85176200000 |

All of our products ensure maximum reliability even in challenging working conditions and help your business operations run smoothly. The products we offer in industrial automation, energy management, cabling solutions, and many other areas adapt flexibly to the needs of different sectors.

Additionally, our products are manufactured using only high-quality materials and comply with international standards. Through the solutions we provide, we enable our customers to increase operational efficiency and optimize costs. Our company closely follows technological advancements and continuously offers innovative products to help our customers gain a competitive advantage.

On each of our product pages, you can find comprehensive information about technical details, areas of use, and product features. You can explore all the products you need to strengthen your industrial processes on our website and enjoy a seamless purchasing experience.

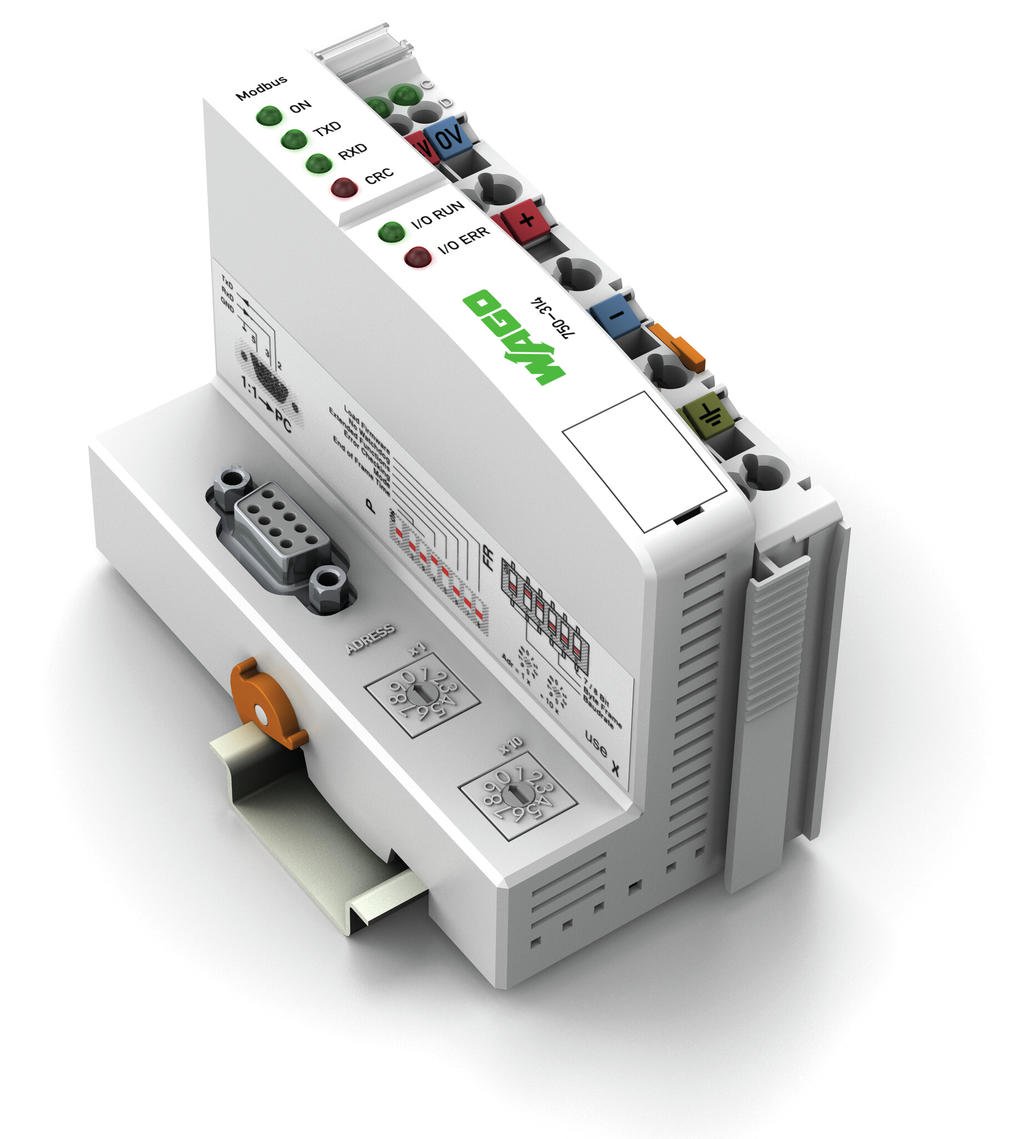

Similar Products

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.