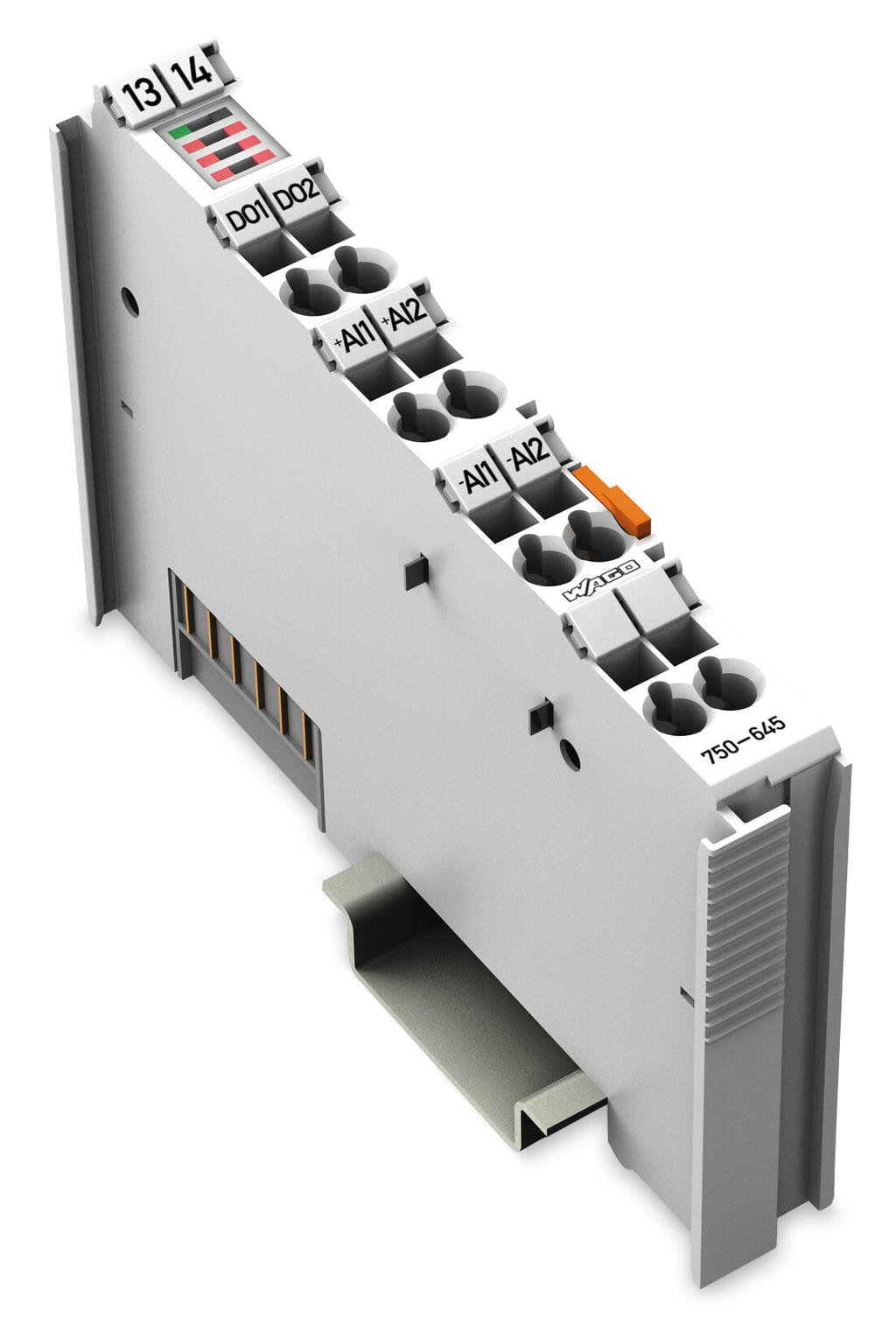

Wago : 750-645

VIB I/O, 2-channel vibration speed/bed condition monitoring.

750-645

2-channel, vibration rate/bearing condition monitoring VIB I/O; Light greyVIB I/O modules are used for online monitoring of machine vibration level. It records the two most important parameters required for condition analysis: degree of vibration and bearing housing condition. Vibration rating is a measurement of the vibration energy of the machine and is therefore a suitable indicator of the vibration forces operating in the machine. To evaluate the results, the ISO 10816-3 standard is used, where the (measured) effective vibration values are divided into three quality categories. The condition of the bearing housing is evaluated based on high-frequency shock pulse signals. Shock pulses are instantaneous impacts caused by mechanical damage to the bearing housing or bearing surface. The evaluation uses a scale in which the measured shock pulses are divided into three bearing condition categories: "good," "limited," and "poor." By recording the measurement results and evaluating them in a trend curve, bearing damage can be detected at an early stage. The exclusive Tandem-Piezo ® acceleration sensor also enables measurements of machine vibrations and high-frequency shock pulses.

2-channel, vibration rate/bearing condition monitoring VIB I/O; Light grey

VIB I/O modules are used for online monitoring of machine vibration level. It records the two most important parameters required for condition analysis: degree of vibration and bearing housing condition.

Vibration rating is a measurement of the vibration energy of the machine and is therefore a suitable indicator of the vibration forces operating in the machine. To evaluate the results, the ISO 10816-3 standard is used, where the (measured) effective vibration values are divided into three quality categories.

The condition of the bearing housing is evaluated based on high-frequency shock pulse signals. Shock pulses are instantaneous impacts caused by mechanical damage to the bearing housing or bearing surface.

The evaluation uses a scale in which the measured shock pulses are divided into three bearing condition categories: "good," "limited," and "poor." By recording the measurement results and evaluating them in a trend curve, bearing damage can be detected at an early stage.

The exclusive Tandem-Piezo ® acceleration sensor also enables measurements of machine vibrations and high-frequency shock pulses.

| Number of digital outputs | 2 |

| Giriş sayısı | 2 |

| Sensör bağlantısı | +AI1, -AI1, +AI2, -AI2 |

| Output current per channel | 0,5A |

| Çıkış akımı | short-circuit-protected |

| Çıkış gerilimi | DC 24 V |

| Titreşim hızı | 0 - 100mm/s |

| Darbe palsı | -10 ... +80 dbSV |

| System supply voltage | DC 5 V; via data contacts |

| Current consumption, system supply (5 V) | 30mA |

| Field supply voltage | DC 24 V (-15 … +20 %); über Leistungskontakte (Einspeisung über Messerkontakt; Weiterleitung über Federkontakt) |

| İzolasyon | 500 V sistem/besleme |

| Number of incoming power jumper contacts | 2 |

| Number of outgoing power jumper contacts | 2 |

| Connection technology: In-/Outputs | 8 x CAGE CLAMP® |

| Connection type (1) | Inputs/Outputs |

| Tek damarlı boylar | 0,08 … 2,5 mm² / 28 … 14 AWG |

| İnce bükümlü kablolar | 0,08 … 2,5 mm² / 28 … 14 AWG |

| Sıyırma uzunluğu | 8 … 9 mm / 0.31 … 0.35 inch |

| Width | 12 mm / 0.472 inch |

| Height | 67,8 mm / 2.669 inch |

| DIN rayın üst kenarından yükseklik | 60,6 mm / 2.386 inch |

| Depth | 100 mm / 3.937 inch |

| Montaj tipi | DIN 35 ray |

| Renk | açık gri |

| Gövde malzemesi | Polycarbonate, polyamide 6.6 |

| Ağırlık | 65 |

| Uygunluk işareti | CE |

| Surrounding air (operating) temperature | 0 … 55 °C |

| Surrounding air (storage) temperature | -40 … 85 °C |

| Koruma sınıfı | IP20 |

| Kirlilik derecesi (5) | 2 per IEC 61131-2 |

| Çalışma yüksekliği | 0 … 2000 m |

| Montaj pozisyonu | horizontal (standing/lying) or vertical |

| Nısbi nem (yoğuşmasız) | 95% |

| Titreşime dayanıklı | acc. to IEC 60068-2-6 |

| Darbe direnci | 15g per IEC 60068-2-27 |

| EMV-Störfestigkeit | acc. to EN 61000-6-2 |

| EMU: |

acc. to EN 61000-6-3 |

| Kirletici maddelere maruziyet | Per IEC 60068-2-42 and IEC 60068-2-43 |

| Permissible H2S contaminant concentration at a relative humidity |

10ppm |

| Permissible SO2 contaminant concentration at a relative humidity |

25ppm |

| Product Group | 15 (Remote I/O) |

| SAP´den ambalaj tipi | BOX |

| Country of origin | DE |

| GTIN | 4045454727451 |

| Customs Tariff No. | 85389099990 |

All of our products ensure maximum reliability even in challenging working conditions and help your business operations run smoothly. The products we offer in industrial automation, energy management, cabling solutions, and many other areas adapt flexibly to the needs of different sectors.

Additionally, our products are manufactured using only high-quality materials and comply with international standards. Through the solutions we provide, we enable our customers to increase operational efficiency and optimize costs. Our company closely follows technological advancements and continuously offers innovative products to help our customers gain a competitive advantage.

On each of our product pages, you can find comprehensive information about technical details, areas of use, and product features. You can explore all the products you need to strengthen your industrial processes on our website and enjoy a seamless purchasing experience.

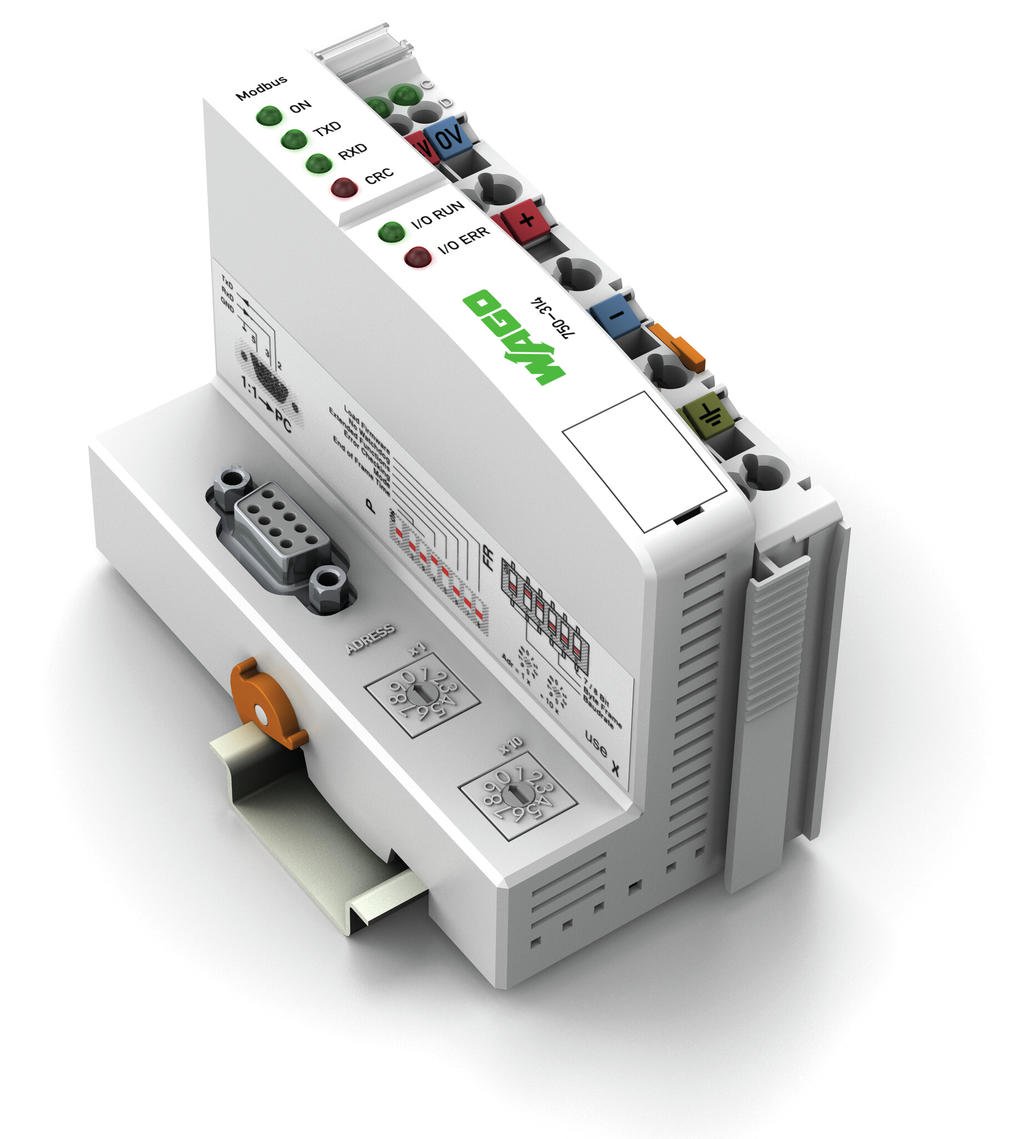

Similar Products

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.