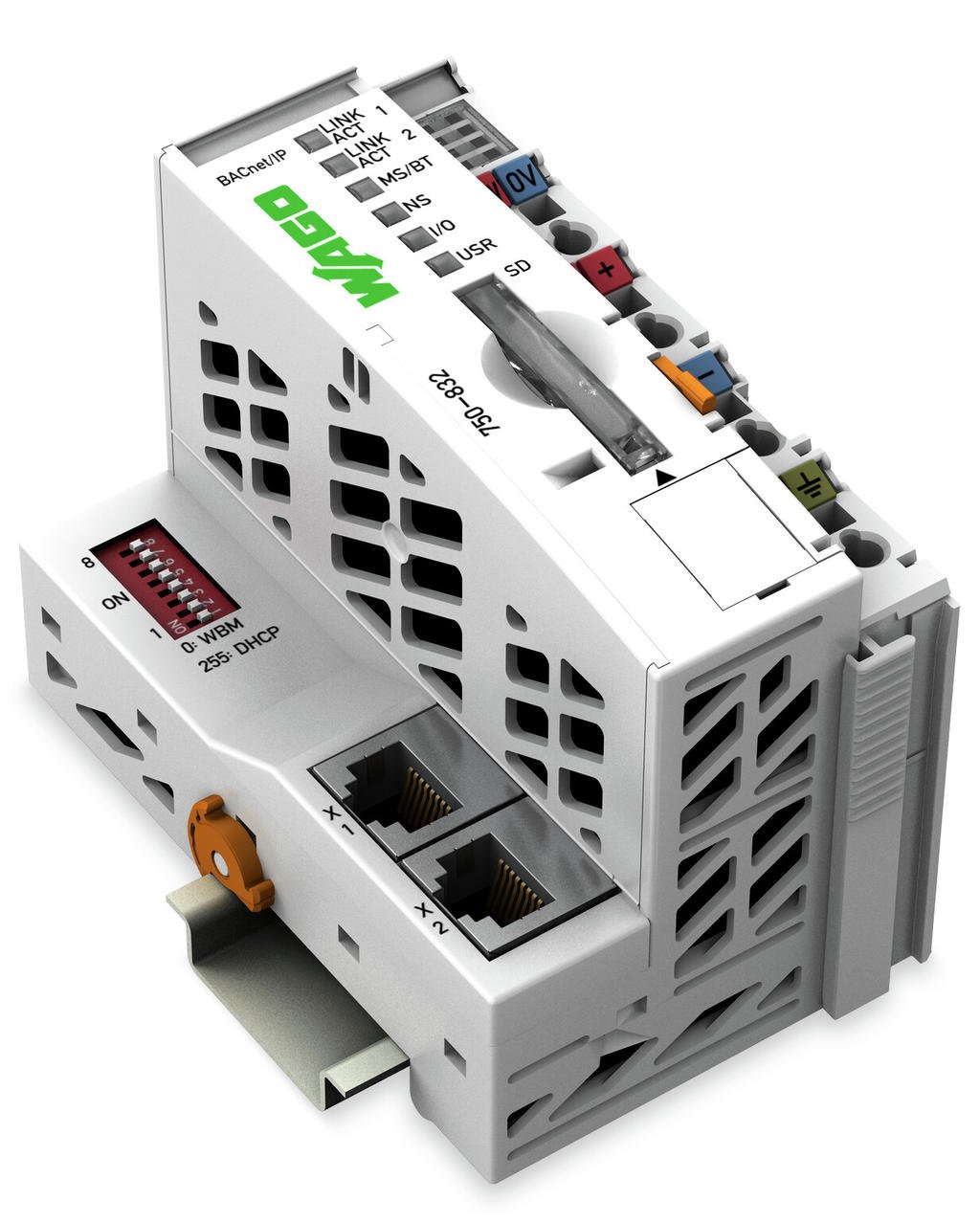

Wago : 750-832

Controller BACnet/IP

750-832

Kontrolör BACnet/IP; 4. nesil; 2 x ETHERNET, SD Ethernet kartı; açık gri The 750‐832 BACnet/IP Controller connects the WAGO‐I/O-SYSTEM to the BACnet protocol and supports the B‐BC BACnet device profile per DIN EN ISO 16484‐5. It communicates with other BACnet devices via BACnet/IP.The controller provides the three following functionalities:1. Native server: For each channel, appropriate BACnet objects are generated automatically for the digital and analog I/O modules that are connected to the controller.2. Application server: Other supported BACnet objects can be created via the IEC 61131‐3 programming environment and made available to a BACnet network.3. Application client: Using the client functionality, objects and their properties can be accessed by other BACnet devices.Two ETHERNET interfaces and an integrated switch allow the fieldbus to be wired in a line topology, eliminating the need for additional network devices, such as switches or hubs. Both interfaces support autonegotiation and Auto-MDI(X).The DIP switch configures the last byte of the IP address and may be used for IP address assignment. An integrated Webserver provides configuration options to the user, while displaying controller’s status information. The IEC 61131-3 programmable controller is multitasking-capable and features a battery-backed RTC. A data memory of 8 MB is available.The 750-832 Controller is equipped with a removable memory card slot. A memory card can be used to transfer device parameters or files (e.g., boot files) from one controller to another. The memory card can be accessed via FTP and be used as an additional drive.The controller can process a maximum of 1000 simple BACnet objects. The actual number that can be implemented in the project can be reduced with complex object types.Start-up and configuration of the BACnet networks is performed using the Windows software WAGO BACnet Configurator.Note:The WAGO BACnet Configurator can be downloaded for free at www.wago.com.

Kontrolör BACnet/IP; 4. nesil; 2 x ETHERNET, SD Ethernet kartı; açık gri

The 750‐832 BACnet/IP Controller connects the WAGO‐I/O-SYSTEM to the BACnet protocol and supports the B‐BC BACnet device profile per DIN EN ISO 16484‐5. It communicates with other BACnet devices via BACnet/IP.

The controller provides the three following functionalities:

1. Native server: For each channel, appropriate BACnet objects are generated automatically for the digital and analog I/O modules that are connected to the controller.

2. Application server: Other supported BACnet objects can be created via the IEC 61131‐3 programming environment and made available to a BACnet network.

3. Application client: Using the client functionality, objects and their properties can be accessed by other BACnet devices.

Two ETHERNET interfaces and an integrated switch allow the fieldbus to be wired in a line topology, eliminating the need for additional network devices, such as switches or hubs. Both interfaces support autonegotiation and Auto-MDI(X).

The DIP switch configures the last byte of the IP address and may be used for IP address assignment. An integrated Webserver provides configuration options to the user, while displaying controller’s status information.

The IEC 61131-3 programmable controller is multitasking-capable and features a battery-backed RTC. A data memory of 8 MB is available.

The 750-832 Controller is equipped with a removable memory card slot. A memory card can be used to transfer device parameters or files (e.g., boot files) from one controller to another. The memory card can be accessed via FTP and be used as an additional drive.

The controller can process a maximum of 1000 simple BACnet objects. The actual number that can be implemented in the project can be reduced with complex object types.

Start-up and configuration of the BACnet networks is performed using the Windows software WAGO BACnet Configurator.

Note:

The WAGO BACnet Configurator can be downloaded for free at www.wago.com.

| İletişim | BACnet/IP Modbus TCP |

| Protokoller | HTTP(S) BootP DHCP DNS SNTP (S)FTP SNMP |

| Visualization | Web-Visu |

| CPU | 32 bits |

| Programming languages per IEC 61131-3 | Instruction List (IL) Ladder Diagram (LD) Function Block Diagram (FBD), Continuous Function Chart (CFC) Structured Text (ST) Sequential Function Chart (SFC) |

| Programlama | WAGO-I/O-PRO V2.3 |

| Configuration options | WAGO-I/O-CHECK BACnet Configurator Web-based management |

| Baud rate (communication/fieldbus 1) | 10/100 Mbit/s |

| Baud rate | 10/100 Mbit/s |

| Transmission medium (communication/fieldbus) | Twisted Pair S-UTP; 100 Ω; Cat. 5; Line length (max.): 100 m |

| İletim performansı | D Sınıfı, EN 50173´e göre |

| Program memory | 8.192 MB |

| Data memory | 8.192 MB |

| Software non-volatile memory | 32kbyte |

| Hafıza kartı tipi | 32 GB´a kadar SD ve SDHC (Garanti edilen tüm özellikler sadece WAGO 758-879/000-001 hafıza kartı ile geçerlidir.) |

| Memory card slot | Push-push mechanism, sealable cover lid |

| I/O modülü sayısı (düğüm başına) | 250 |

| Number of I/O modules without bus extension max. | 64 |

| Input and output process image (Fieldbus) max. | 1020 Worte/1020 Worte |

| Device-specific | BACnet device profile: B-BC (BACnet Building Controller); BACnet version: 12 |

| Indicators | LED (LINK/ACT) green: Network connection Port 1 … 2; LED (MS/BT, NS) red/green: Status of node/BACnet, network; LED (I/O, USR) red/green/orange: Internal data bus status, status programmable by user; LED (A, B) green: System power supply status, field supply |

| System supply voltage | DC 24 V(-25 … +30 %); via wiring level (CAGE CLAMP® connection) |

| Anma yükünde giriş akımı tip. (24 V) | 500mA |

| Nominal yükte güç kaynağı verimi (tip.) (24 V) | 90% |

| Current consumption, system supply (5 V) | 440mA |

| Total current for system supply | 1.700mA |

| Field supply voltage | DC 24 V (-25 … +30 %); via power jumper contacts |

| Current carrying capacity of the power jumper contacts | 10A |

| Number of outgoing power jumper contacts | 3 |

| İzolasyon | 500 V sistem/besleme |

| Connection technology: communication/fieldbus | BACnet/IP: 2 x RJ-45; Modbus TCP/UDP: 2 x RJ-45 |

| Connection technology: system supply | 2 x CAGE CLAMP® |

| Connection technology: field supply | 6 x CAGE CLAMP® |

| Connection type (1) | System/field supply |

| Tek damarlı boylar | 0,08 … 2,5 mm² / 28 … 14 AWG |

| İnce bükümlü kablolar | 0,08 … 2,5 mm² / 28 … 14 AWG |

| Sıyırma uzunluğu | 8 … 9 mm / 0.31 … 0.35 inch |

| Connection technology: Device configuration | 1 x 4-pole male connector |

| Width | 61,5 mm / 2.421 inch |

| Height | 71,9 mm / 2.831 inch |

| DIN rayın üst kenarından yükseklik | 64,7 mm / 2.547 inch |

| Depth | 100 mm / 3.937 inch |

| Ağırlık | 151,8 |

| Renk | açık gri |

| Gövde malzemesi | Polycarbonate, polyamide 6.6 |

| Surrounding air (operating) temperature | 0 … 55 °C |

| Surrounding air (storage) temperature | -40 … 85 °C |

| Koruma sınıfı | IP20 |

| Kirlilik derecesi (5) | 2 per IEC 61131-2 |

| Çalışma yüksekliği | without temperature derating: 0 … 2000 m; with temperature derating: 2000 … 5000 m (0.5 K/100 m); max.: 5000 m |

| Nısbi nem (yoğuşmasız) | 95% |

| Montaj pozisyonu | herhangi |

| Montaj tipi | DIN 35 ray |

| Titreşime dayanıklı | 4g per IEC 60068-2-6 |

| Darbe direnci | 15g per IEC 60068-2-27 |

| EMV-Störfestigkeit | acc. to EN 61000-6-2 |

| EMU: |

acc. to EN 61000-6-3 |

| Kirletici maddelere maruziyet | Per IEC 60068-2-42 and IEC 60068-2-43 |

| Permissible H2S contaminant concentration at a relative humidity |

10ppm |

| Permissible SO2 contaminant concentration at a relative humidity |

25ppm |

| SAP´den ambalaj tipi | BOX |

| Country of origin | DE |

| GTIN | 4055143888561 |

| Customs Tariff No. | 85371091990 |

All of our products ensure maximum reliability even in challenging working conditions and help your business operations run smoothly. The products we offer in industrial automation, energy management, cabling solutions, and many other areas adapt flexibly to the needs of different sectors.

Additionally, our products are manufactured using only high-quality materials and comply with international standards. Through the solutions we provide, we enable our customers to increase operational efficiency and optimize costs. Our company closely follows technological advancements and continuously offers innovative products to help our customers gain a competitive advantage.

On each of our product pages, you can find comprehensive information about technical details, areas of use, and product features. You can explore all the products you need to strengthen your industrial processes on our website and enjoy a seamless purchasing experience.

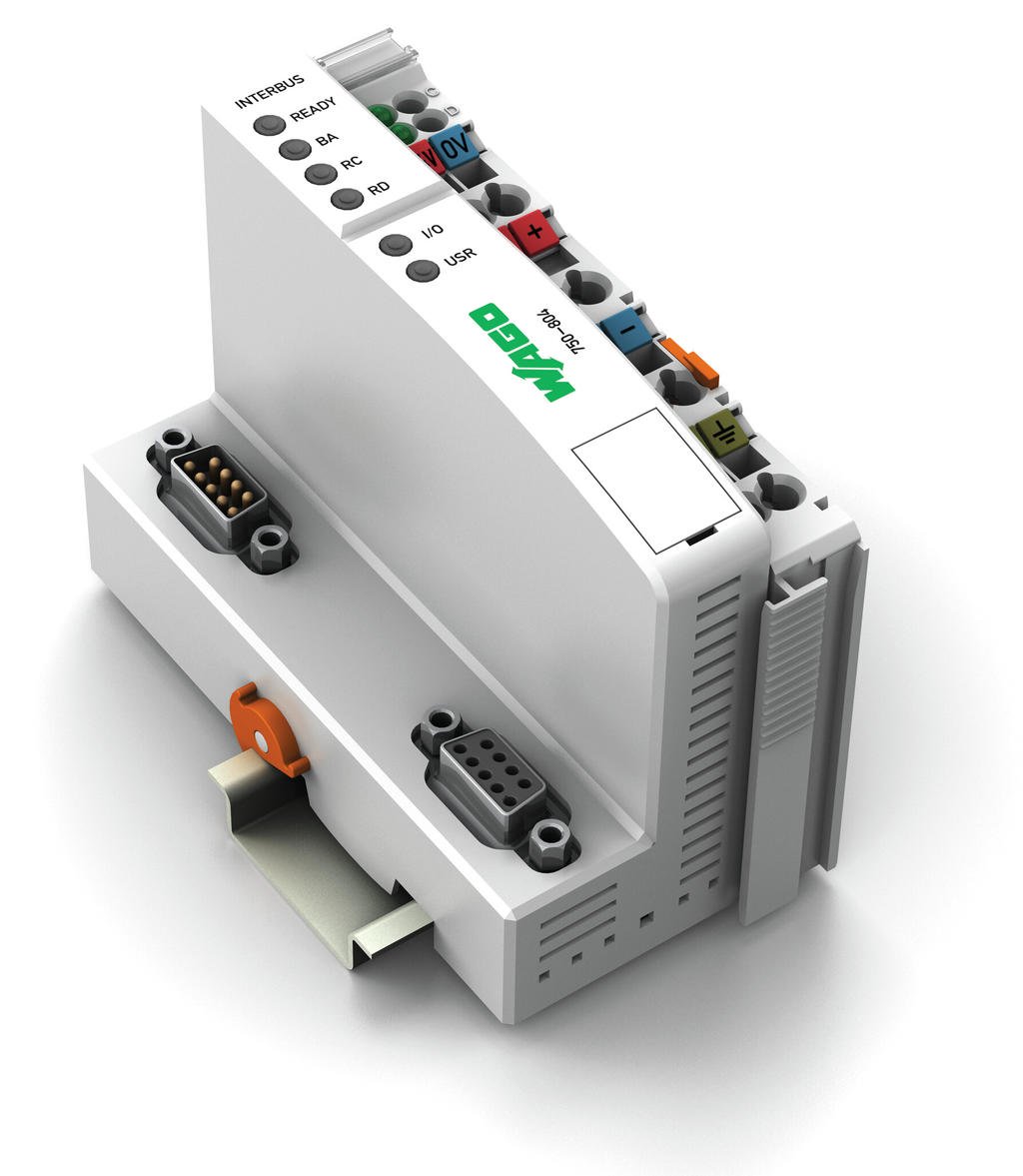

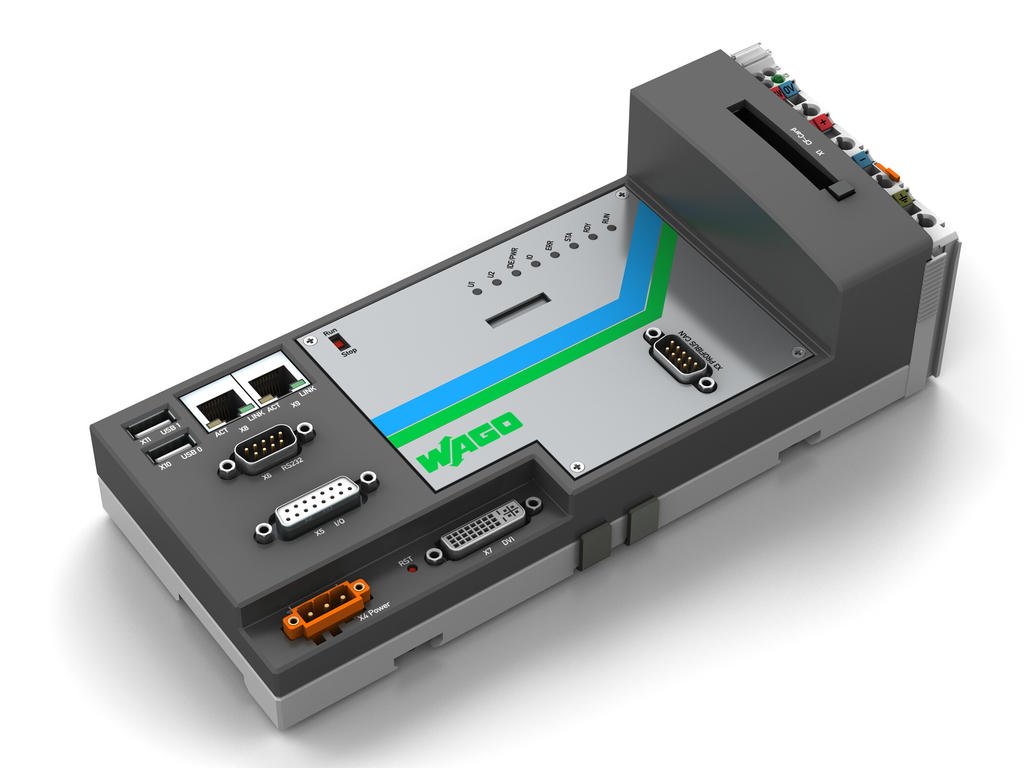

Similar Products

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.