| Product range |

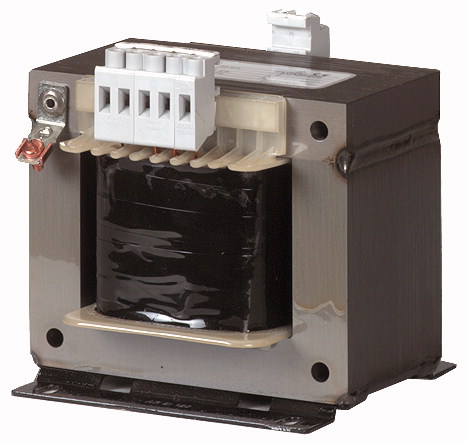

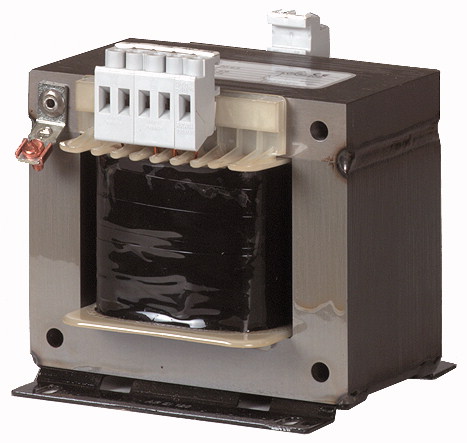

Single-phase control transformers ST... |

| Basic function |

Single-phase control, isolating and safety transformers STI, STZ |

| Rated input voltage |

400± 5 % V |

| Rated output voltage |

230 V |

| Rated power |

1 kVA |

| Short-time rating |

2.8 kVA |

| Terminal diagram / contact assignment |

|

| Cu factor |

2,20 kg |

Standards

>Built and tested to |

|

Standards

>Suitable for use to |

IEC/EN 61558-2-2/2-4/2-6

VDE 0570 Part 2-2

VDE 0570 Part 2‐6 (safety transformers)

VDE 0570 Part 2-4 (isolating transformer) |

| Ambient temperature |

IEC/EN 60204-1, ÖVE-EN 13

VDE 0113, VDE 0100 Part 410 |

| Terminations |

-25 - 40 |

| Connection lugs |

|

| Insulation class |

● (< 115 A) |

| Rated frequency |

● (> 115 A) |

| Primary tapping |

B |

| Degree of Protection |

50 - 60 Hz |

| Separate windings |

± 5 % |

| Fully vacuum-impregnated |

IP00 |

| Reinforced insulation |

● |

| Rated duty factor |

● |

| Note |

● |

| Total weight |

100 % DF |

| No-load losses |

|

| Short-circuit losses |

The following applies for the no-load loss, short-circuit loss (copper losses), short-circuit voltage and efficiency values: all details relate to a temperature of 20 °C |

| Shortcircuit voltage |

13.4 kg |

| Efficiency |

27 W |

| Rated operational current for specified heat dissipation [In] |

29 W |

| Heat dissipation per pole, current-dependent [Pvid] |

2.9 % |

| Equipment heat dissipation, current-dependent [Pvid] |

0.95 |

| Static heat dissipation, non-current-dependent [Pvs] |

|

| Heat dissipation capacity [Pdiss] |

0 A |

| Operating ambient temperature min. |

0 W |

| Operating ambient temperature max. |

0 W |

10.2 Strength of materials and parts

>10.2.2 Corrosion resistance |

56 W |

10.2 Strength of materials and parts

>10.2.3.1 Verification of thermal stability of enclosures |

0 W |

10.2 Strength of materials and parts

>10.2.3.2 Verification of resistance of insulating materials to normal heat |

-25 °C |

10.2 Strength of materials and parts

>10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

+40 °C |

10.2 Strength of materials and parts

>10.2.4 Resistance to ultra-violet (UV) radiation |

|

10.2 Strength of materials and parts

>10.2.5 Lifting |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.6 Mechanical impact |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.7 Inscriptions |

Meets the product standard´s requirements. |

| 10.3 Degree of protection of ASSEMBLIES |

Meets the product standard´s requirements. |

| 10.4 Clearances and creepage distances |

Meets the product standard´s requirements. |

| 10.5 Protection against electric shock |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.6 Incorporation of switching devices and components |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.7 Internal electrical circuits and connections |

Meets the product standard´s requirements. |

| 10.8 Connections for external conductors |

Does not apply, since the entire switchgear needs to be evaluated. |

10.9 Insulation properties

>10.9.2 Power-frequency electric strength |

Meets the product standard´s requirements. |

10.9 Insulation properties

>10.9.3 Impulse withstand voltage |

Does not apply, since the entire switchgear needs to be evaluated. |

10.9 Insulation properties

>10.9.4 Testing of enclosures made of insulating material |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.10 Temperature rise |

Is the panel builder´s responsibility. |

| 10.11 Short-circuit rating |

Is the panel builder´s responsibility. |

| 10.12 Electromagnetic compatibility |

Is the panel builder´s responsibility. |

| 10.13 Mechanical function |

Is the panel builder´s responsibility. |

| Built as safety transformer |

Is the panel builder´s responsibility. |

| Built as isolating transformer |

The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| Built as energy saving transformer |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| Primary voltage 1 |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| Primary voltage 2 |

The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| Primary voltage 3 |

|

| Primary voltage 4 |

|

| Primary voltage 5 |

Yes |

| Primary voltage 6 |

Yes |

| Primary voltage 7 |

No |

| Primary voltage 8 |

400 - 400 V |

| Primary voltage 9 |

0 - 0 V |

| Primary voltage 10 |

0 - 0 V |

| Secondary voltage 1 |

0 - 0 V |

| Secondary voltage 2 |

0 - 0 V |

| Secondary voltage 3 |

0 - 0 V |

| Secondary voltage 4 |

0 - 0 V |

| Secondary voltage 5 |

0 - 0 V |

| Secondary voltage 6 |

0 - 0 V |

| Secondary voltage 7 |

0 - 0 V |

| Secondary voltage 8 |

230 - 230 V |

| Secondary voltage 9 |

0 - 0 V |

| Secondary voltage 10 |

0 - 0 V |

| Rated apparent power |

0 - 0 V |

| Type of insulation material acc. IEC 85 |

0 - 0 V |

| Short-circuit-proof |

0 - 0 V |

| Relative short circuit voltage |

0 - 0 V |

| Width |

0 - 0 V |

| Height |

0 - 0 V |

| Depth |

0 - 0 V |

| Degree of protection (IP) |

1000 VA |

| Ring core |

B |

| Suitable for mounting on PCB |

No |

| Modular version |

2.9 % |

| Conductor material |

151 mm |

| Product Standards |

211 mm |

| UL File No. |

150 mm |

| UL Category Control No. |

IP00 |

| CSA File No. |

No |

| CSA Class No. |

No |

| North America Certification |

No |

| Specially designed for North America |

Copper |

| Suitable for |

UL 506; UL5085-1; UL 5085-2; CSA-C22.2 No. 66; CSA-C22.2 No. 66.1-06; CSA-C22.2 No. 66.2-06; IEC/EN 61558-2-2; CE marking |

| Max. Voltage Rating |

E167225 |

| Degree of Protection |

XPTQ2, XPTQ8 |