| Product range |

PKM0 motor protective circuit-breakers up to 32 A |

| Basic function |

Short-circuit protective device only |

| Notes |

|

| Connection technique |

Also suitable for motors with efficiency class IE3.

IE3-ready devices are identified by the logo on their packaging. |

| Contact sequence |

Screw terminals |

AC-3

>220 V 230 V 240 V [P] |

|

AC-3

>380 V 400 V 415 V [P] |

|

AC-3

>440 V [P] |

1.1 kW |

AC-3

>500 V [P] |

2.2 kW |

AC-3

>660 V 690 V [P] |

3 kW |

| Rated uninterrupted current [Iu] |

3 kW |

short-circuit release [Irm

] [Irm

]

>max. [Irm

] |

4 kW |

| Notes |

6.3 A |

| Notes |

|

| Standards |

97.7 A |

| Climatic proofing |

An appropriate overload relay must be fitted to protect motors against overload.

Can be snapped on to IEC/EN 60715 top-hat rail with 7.5 or 15 mm height.

Refer to catalog CA034001DE for the allocation of short circuit protection and contactor |

Ambient temperature

>Storage |

| Beim Einsatz des PKM0 als Kurzschlussschutz von schwer anlaufenden Motoren muss der Bemessungsbetriebsstrom Ie bei der Projektierung der Schaltgeräte mit den folgenden Faktoren überdimensioniert werden: |

|---|

| CLASS 5: | 1,0 | | CLASS 10: | 1,0 | | CLASS 15: | 1,22 | | CLASS 20: | 1,41 | | CLASS 25: | 1,58 | | CLASS 30: | 1,73 | | CLASS 35: | 1,89 | | CLASS 40: | 2,0 |

|

Ambient temperature

>Open |

|

Ambient temperature

>Enclosed |

IEC/EN 60947, VDE 0660 |

| Mounting position |

Damp heat, constant, to IEC 60068-2-78

Damp heat, cyclic, to IEC 60068-2-30 |

| Direction of incoming supply |

- 40 - 80 °C |

Degree of protection

>Device |

-25 - +55 °C |

Degree of protection

>Terminations |

- 25 - 40 °C |

| Protection against direct contact when actuated from front (EN 50274) |

|

| Mechanical shock resistance half-sinusoidal shock 10 ms to IEC 60068-2-27 |

as required |

| Altitude |

IP20 |

Terminal capacity main cable

>Screw terminals

>Solid |

IP00 |

Terminal capacity main cable

>Screw terminals

>Flexible with ferrule to DIN 46228 |

Finger and back-of-hand proof |

Terminal capacity main cable

>Screw terminals

>Solid or stranded |

25 g |

Terminal capacity main cable

>Screw terminals

>Stripping length |

Max. 2000 m |

Specified tightening torque for terminal screws

>Main cable |

1 x (1 - 6)

2 x (1 - 6) mm2 |

Specified tightening torque for terminal screws

>Control circuit cables |

1 x (1 - 6)

2 x (1 - 6) mm2 |

| Rated impulse withstand voltage [Uimp] |

18 - 10 AWG |

| Overvoltage category/pollution degree |

10 mm |

| Rated operational voltage [Ue

] |

1.7 Nm |

| Rated uninterrupted current = rated operational current [Iu = Ie

] |

1 Nm |

| Rated frequency [f] |

|

| Current heat loss (3 pole at operating temperature) |

6000 V AC |

| Impedance per pole |

III/3 |

| Lifespan, mechanical [Operations] |

690 V AC |

Lifespan, electrical (AC-3 at 400 V)

>Lifespan, electrical [Operations] |

6.3 A |

| Max. operating frequency |

40 - 60 Hz |

Motor switching capacity

>AC-3 (up to 690V) |

5.68 W |

Motor switching capacity

>DC-5 (up to 250V) |

46 mΩ |

Temperature compensation

>to IEC/EN 60947, VDE 0660 |

0.1 x 106 |

Temperature compensation

>Operating range |

0.1 x 106

|

| Temperature compensation residual error for T > 40 °C |

40 Ops/h |

| short-circuit release |

6.3 A |

| Short-circuit release tolerance |

6.3 (3 contacts in series) A |

| Rated operational current for specified heat dissipation [In] |

|

| Heat dissipation per pole, current-dependent [Pvid] |

- 5…40 °C |

| Equipment heat dissipation, current-dependent [Pvid] |

- 25…55 °C |

| Static heat dissipation, non-current-dependent [Pvs] |

≦ 0.25 %/K |

| Heat dissipation capacity [Pdiss] |

Basic device, fixed: 15.5 x Iu |

| Operating ambient temperature min. |

± 20% |

| Operating ambient temperature max. |

|

10.2 Strength of materials and parts

>10.2.2 Corrosion resistance |

6.3 A |

10.2 Strength of materials and parts

>10.2.3.1 Verification of thermal stability of enclosures |

1.89 W |

10.2 Strength of materials and parts

>10.2.3.2 Verification of resistance of insulating materials to normal heat |

5.68 W |

10.2 Strength of materials and parts

>10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

0 W |

10.2 Strength of materials and parts

>10.2.4 Resistance to ultra-violet (UV) radiation |

0 W |

10.2 Strength of materials and parts

>10.2.5 Lifting |

-25 °C |

10.2 Strength of materials and parts

>10.2.6 Mechanical impact |

+55 °C |

10.2 Strength of materials and parts

>10.2.7 Inscriptions |

|

| 10.3 Degree of protection of ASSEMBLIES |

Meets the product standard´s requirements. |

| 10.4 Clearances and creepage distances |

Meets the product standard´s requirements. |

| 10.5 Protection against electric shock |

Meets the product standard´s requirements. |

| 10.6 Incorporation of switching devices and components |

Meets the product standard´s requirements. |

| 10.7 Internal electrical circuits and connections |

Meets the product standard´s requirements. |

| 10.8 Connections for external conductors |

Does not apply, since the entire switchgear needs to be evaluated. |

10.9 Insulation properties

>10.9.2 Power-frequency electric strength |

Does not apply, since the entire switchgear needs to be evaluated. |

10.9 Insulation properties

>10.9.3 Impulse withstand voltage |

Meets the product standard´s requirements. |

10.9 Insulation properties

>10.9.4 Testing of enclosures made of insulating material |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.10 Temperature rise |

Meets the product standard´s requirements. |

| 10.11 Short-circuit rating |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.12 Electromagnetic compatibility |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.13 Mechanical function |

Is the panel builder´s responsibility. |

| Overload release current setting |

Is the panel builder´s responsibility. |

| Adjustment range undelayed short-circuit release |

Is the panel builder´s responsibility. |

| With thermal protection |

Is the panel builder´s responsibility. |

| Phase failure sensitive |

Is the panel builder´s responsibility. |

| Switch off technique |

The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| Rated operating voltage |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| Rated permanent current Iu |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| Rated operation power at AC-3, 230 V |

The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| Rated operation power at AC-3, 400 V |

|

| Type of electrical connection of main circuit |

|

| Type of control element |

0 - 0 A |

| Device construction |

98 - 98 A |

| With integrated auxiliary switch |

No |

| With integrated under voltage release |

No |

| Number of poles |

Magnetic |

| Rated short-circuit breaking capacity lcu at 400 V, AC |

690 - 690 V |

| Degree of protection (IP) |

6.3 A |

| Height |

1.1 kW |

| Width |

2.2 kW |

| Depth |

Screw connection |

| Specially designed for North America |

Turn button |

| Accessories |

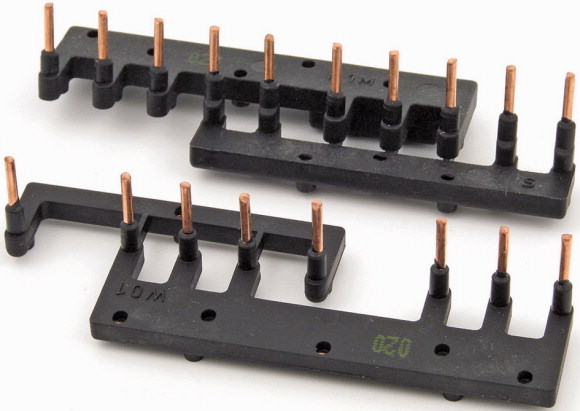

Built-in device fixed built-in technique |

| Characteristic curve |

No |

| Characteristic curve |

No |