| Product range |

Electronic motor starter |

| Product range |

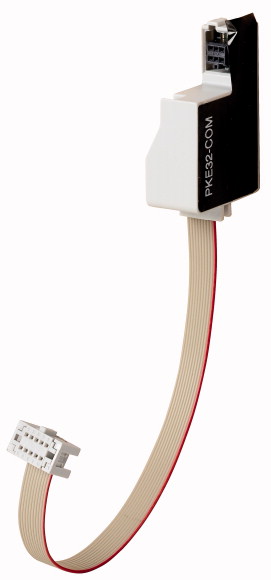

SmartWire-DT slave |

| Subrange |

SmartWire-DT electronic motor starters |

| Basic function |

DOL starters (complete devices) |

| Function |

For connecting to SmartWire-DT for expanded diagnostics. |

| Description |

DOL starting

Motor protection

Circuit design: safety output stage with bypass, three-phase disconnect.

Motor current additionally adjustable via SmartWire-DT. |

| Messages |

Operational readiness

Operating direction feedback

Motor current in %

Motor current in A

Thermal motor image in %

Overload prewarning

Trip indications (overload, phase failure, etc.)

Set short-circuit release value

Device Type |

| Commands |

Operating the motor starter

Manual reset

Automatic reset |

Max. rating for three-phase motors, 50 - 60 Hz

>AC-53a

>380 V 400 V 415 V [P] |

0.55 - 3 kW |

Setting range of overload releases [Ir] [Ir] |

1,5 - 7 (AC-53a)

9 (AC-51) A_x |

| Actuating voltage |

24 V DC |

| Connection technique |

Push in terminals |

| Connection to SmartWire-DT |

yes |

| Standards |

IEC/EN 60947-4-2 |

Dimensions

>Width |

30 mm |

Dimensions

>Height |

157 mm |

Dimensions

>Depth |

124 mm |

| Weight |

0.3 kg |

| Mounting |

Top-hat rail IEC/EN 60715, 35 mm |

| Protection type (IEC/EN 60529, EN50178, VBG 4) |

IP20 |

| Mounting position |

Vertical |

| Lifespan, electrical [Operations] |

3 x 107 |

| Max. switching frequency |

7200 (pulse pause time 50:50) Operations/h |

Terminal capacity

>Solid |

1 x (0.2 - 2.5)

1 x AWG20 - 14 mm2 |

Terminal capacity

>flexible, with ferrule |

2 x (0,2 - 2,5)

1 x AWG24 - 14 mm2

|

Terminal capacity

>Notes |

Minimum length 10 mm. |

Terminal capacity

>flexible, with twin ferrule |

2 x (0,2 - 1,5)

2 x AWG24 - 16 mm2

|

Terminal capacity

>Notes |

Minimum length 10 mm. |

| Operating ambient temperature |

-5 - +60, in accordance with IEC 60068-2-1 °C |

| Storage [ϑ] |

-40 - +80 °C |

| Rated impulse withstand voltage [Uimp] |

6000 V AC |

| Overvoltage category/pollution degree |

III/2 |

| Rated operational voltage [Ue

] |

42 - 550 V |

Rated operational current

>AC-51 [Ie] |

1.20 - 9 A |

Rated operational current

>AC-53a [Ie] |

1.20 - 7 A |

| Heat dissipation [PV] |

1 - 12 W |

| Static heat dissipation, non-current-dependent [Pvs] |

1 W |

Basic insulation to IEC/EN60947-1

>Between supply, control, and switching voltages |

500 V AC |

Basic insulation to IEC/EN60947-1

>between feedback signal output and switch voltage |

500 V AC |

Current measurement

>Setting range of overload releases [Ir] [Ir] |

1,5 - 7 (AC-53a)

9 (AC-51) A_x |

Current measurement

>Release class |

10 (Ir ≦ 4 A)

10A (Ir > 4 A) CLASS |

Current measurement

>Recovery time [tW] |

2 (manual startup)

20 (automatic restart) min. |

Current measurement

>Balance monitoring

>Magnitude Imax > Irated ((Imax - Imin)/Imax) |

If ≧ 33, pick-up time of 120 s

If ≧ 67, pick-up time of 1.8 s % |

Current measurement

>Balance monitoring

>Magnitude Imax < Irated ((Imax - Imin)/Irated) |

If ≧ 33, pick-up time of 120 s

If ≧ 67, pick-up time of 1.8 s % |

Stall protection

>Pick-up time I (L1) or I (L3) |

60 A |

Stall protection

>Pick-up time |

0.5 S |

Short-circuit rating

>Type “1” coordination

>Short-circuit protective device |

50 kA, 500 V AC: Fuse 16 A gG/gL

50 kA, 500 V AC: fuse 30 A CCMR

50 kA, 415 V AC: PKM0-4

15 kA, 415 V AC: PKM0-6,3

2.5 kA, 400 V AC: FAZ-B16/3 |

Input data

>Supply voltage [UAUX] |

24 (-15 - +20 %) V DC |

Input data

>Residual ripple on the input voltage |

≦ 5 % |

Input data

>Input current |

70 mA |

Input data

>Current draw inrush |

120 mA |

Input data

>Current draw (operation) [UAUX] |

50 mA |

Electrostatic discharge (ESD)

>applied standard |

IEC EN 61000-4-2, Level 3 |

Electrostatic discharge (ESD)

>Air discharge |

8 kV |

Electrostatic discharge (ESD)

>Contact discharge |

6 kV |

Electromagnetic fields (RFI)

>applied standard |

IEC/EN 61000-4-3 |

| Electromagnetic fields (RFI) |

800 - 1000 MHz: 10

1.4 - 2 GHz: 10

2.0 - 2.7 GHz: 3 V/m |

| Radio interference suppression |

EN 55011, Class A (emitted interference, line-conducted)

EN 61000-6-3, Class A (emitted interference, radiated) |

| Note on use |

This product is designed for operation in industrial environments (environment 2). The use in residential environments (environment 1) could cause electrical interference so that addition suppression must be planned. |

| Burst |

2

IEC/EN 61000-4-4, level 3 kV |

| power pulses (Surge) |

1 kV (symmetrical)

2 kV (asymmetrical)

according to IEC/EN 61000-4-5 |

| Immunity to line-conducted interference to (IEC/EN 61000-4-6) |

10 V |

| Rated operational current for specified heat dissipation [In] |

6.5 A |

| Heat dissipation per pole, current-dependent [Pvid] |

2.1 W |

| Equipment heat dissipation, current-dependent [Pvid] |

6.3 W |

| Static heat dissipation, non-current-dependent [Pvs] |

1 W |

| Heat dissipation capacity [Pdiss] |

0 W |

| Operating ambient temperature min. |

-5 °C |

| Operating ambient temperature max. |

+60 °C |

10.2 Strength of materials and parts

>10.2.2 Corrosion resistance |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.3.1 Verification of thermal stability of enclosures |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.3.2 Verification of resistance of insulating materials to normal heat |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.4 Resistance to ultra-violet (UV) radiation |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.5 Lifting |

Does not apply, since the entire switchgear needs to be evaluated. |

10.2 Strength of materials and parts

>10.2.6 Mechanical impact |

Does not apply, since the entire switchgear needs to be evaluated. |

10.2 Strength of materials and parts

>10.2.7 Inscriptions |

Meets the product standard´s requirements. |

| 10.3 Degree of protection of ASSEMBLIES |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.4 Clearances and creepage distances |

Meets the product standard´s requirements. |

| 10.5 Protection against electric shock |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.6 Incorporation of switching devices and components |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.7 Internal electrical circuits and connections |

Is the panel builder´s responsibility. |

| 10.8 Connections for external conductors |

Is the panel builder´s responsibility. |

10.9 Insulation properties

>10.9.2 Power-frequency electric strength |

Is the panel builder´s responsibility. |

10.9 Insulation properties

>10.9.3 Impulse withstand voltage |

Is the panel builder´s responsibility. |

10.9 Insulation properties

>10.9.4 Testing of enclosures made of insulating material |

Is the panel builder´s responsibility. |

| 10.10 Temperature rise |

The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| 10.11 Short-circuit rating |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| 10.12 Electromagnetic compatibility |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| 10.13 Mechanical function |

The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| Kind of motor starter |

Direct starter |

| With short-circuit release |

No |

| Rated control supply voltage Us at AC 50HZ |

0 - 0 V |

| Rated control supply voltage Us at AC 60HZ |

0 - 0 V |

| Rated control supply voltage Us at DC |

24 - 24 V |

| Voltage type for actuating |

DC |

| Rated operation power at AC-3, 230 V, 3-phase |

1.5 kW |

| Rated operation power at AC-3, 400 V |

3 kW |

| Rated power, 460 V, 60 Hz, 3-phase |

2.2 kW |

| Rated power, 575 V, 60 Hz, 3-phase |

0 kW |

| Rated operation current Ie |

9 A |

| Rated operation current at AC-3, 400 V |

7 A |

| Overload release current setting |

1.5 - 9 A |

| Rated conditional short-circuit current, type 1, 480 Y/277 V |

0 A |

| Rated conditional short-circuit current, type 1, 600 Y/347 V |

0 A |

| Rated conditional short-circuit current, type 2, 230 V |

0 A |

| Rated conditional short-circuit current, type 2, 400 V |

0 A |

| Number of auxiliary contacts as normally open contact |

0 |

| Number of auxiliary contacts as normally closed contact |

0 |

| Ambient temperature, upper operating limit |

40 °C |

| Temperature compensated overload protection |

Yes |

| Release class |

CLASS 10 |

| Type of electrical connection of main circuit |

Spring clamp connection |

| Type of electrical connection for auxiliary- and control current circuit |

Spring clamp connection |

| Rail mounting possible |

Yes |

| With transformer |

No |

| Number of command positions |

0 |

| Suitable for emergency stop |

No |

| Coordination class according to IEC 60947-4-3 |

Class 1 |

| Number of indicator lights |

4 |

| External reset possible |

Yes |

| With fuse |

No |

| Degree of protection (IP) |

IP20 |

| Degree of protection (NEMA) |

Other |

| Supporting protocol for TCP/IP |

No |

| Supporting protocol for PROFIBUS |

No |

| Supporting protocol for CAN |

No |

| Supporting protocol for INTERBUS |

No |

| Supporting protocol for ASI |

No |

| Supporting protocol for MODBUS |

No |

| Supporting protocol for Data-Highway |

No |

| Supporting protocol for DeviceNet |

No |

| Supporting protocol for SUCONET |

No |

| Supporting protocol for LON |

No |

| Supporting protocol for PROFINET IO |

No |

| Supporting protocol for PROFINET CBA |

No |

| Supporting protocol for SERCOS |

No |

| Supporting protocol for Foundation Fieldbus |

No |

| Supporting protocol for EtherNet/IP |

No |

| Supporting protocol for AS-Interface Safety at Work |

No |

| Supporting protocol for DeviceNet Safety |

No |

| Supporting protocol for INTERBUS-Safety |

No |

| Supporting protocol for PROFIsafe |

No |

| Supporting protocol for SafetyBUS p |

No |

| Supporting protocol for other bus systems |

Yes |

| Width |

30 mm |

| Height |

157 mm |

| Depth |

139 mm |

| Product Standards |

IEC/EN 60947-5; UL 508; CSA-C22.2 No. 14; CE marking |

| UL File No. |

E29096 |

| UL Category Control No. |

NLDX, NLDX7 |

| CSA File No. |

UL report applies to both US and Canada |

| North America Certification |

UL listed, certified by UL for use in Canada |

| Specially designed for North America |

No |

| Characteristic curve |

|

| Characteristic curve |

Tripping characteristics

CLASS 10

set motor current ≦ 4 A |

| Characteristic curve |

|