Wago : 773-498

This is already in English.

773-498

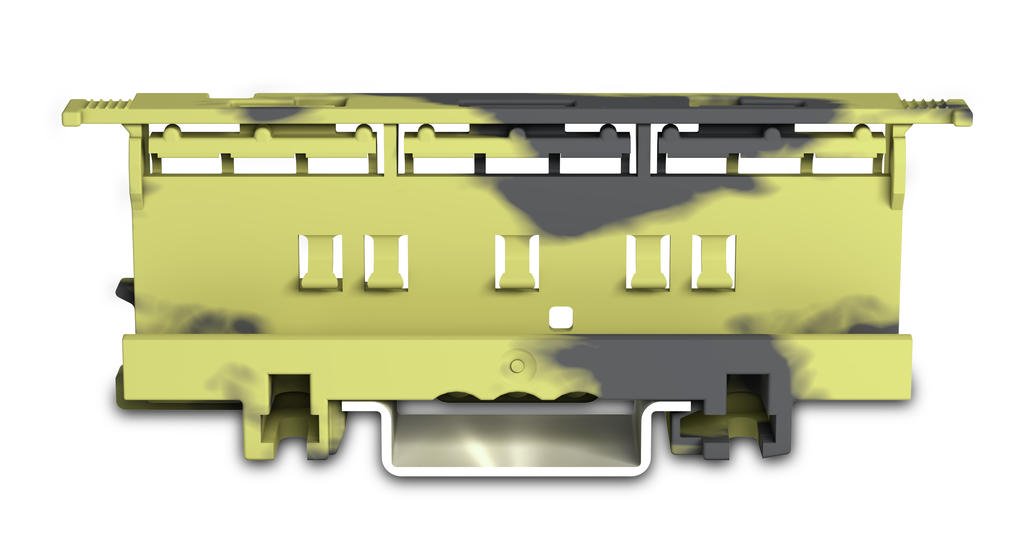

Buatlar için PUSH WIRE® konnektör; tek damarlı, bükümlü iletkenler için; Ex uygulamaları için; maks. 2,5 mm²; 8 iletkenli; açık gri gövde; açık gri kapak; maks. ortam çalışma sıcaklığı 60 °C; 2,50 mm² Note:Terminating Aluminum ConductorsWAGO spring clamp terminal blocks are suitable for solid aluminum conductors up to 4 mm²/12 AWG if WAGO “Alu-Plus” Contact Paste is used for termination.“Alu-Plus” Contact Paste Advantages:Automatically destroys the oxide film during clamping.Prevents fresh oxidation at the clamping point.Prevents electrolytic corrosion between aluminum and copper conductors (in the same terminal block).Provides long-term protection against corrosion.Using terminal blocks with PUSH WIRE® Spring Pressure Connection Technology, aluminum conductors must first be cleaned with a blade and then immediately be inserted into the clamping units filled with “Alu-Plus” Contact Paste.It is also possible to apply WAGO “Alu-Plus” additionally on the whole surface of the aluminum conductor before termination.Please note that the nominal currents must be adapted to the reduced conductivity of the aluminum conductors:2.5 mm² (14 AWG) = 16 A4 mm² (12 AWG) = 22 AGüvenlik bilgisi 1:Diğer potansiyellerin parçalarına < 10mm mesafede 275VGüvenlik bilgisi 2:Sadece 773-331 Montaj Taşıyıcısı ile birlikte kullanılır.

Buatlar için PUSH WIRE® konnektör; tek damarlı, bükümlü iletkenler için; Ex uygulamaları için; maks. 2,5 mm²; 8 iletkenli; açık gri gövde; açık gri kapak; maks. ortam çalışma sıcaklığı 60 °C; 2,50 mm²

Note:

Terminating Aluminum Conductors

WAGO spring clamp terminal blocks are suitable for solid aluminum conductors up to 4 mm²/12 AWG if WAGO “Alu-Plus” Contact Paste is used for termination.

“Alu-Plus” Contact Paste Advantages:

- Automatically destroys the oxide film during clamping.

- Prevents fresh oxidation at the clamping point.

- Prevents electrolytic corrosion between aluminum and copper conductors (in the same terminal block).

- Provides long-term protection against corrosion.

Using terminal blocks with PUSH WIRE® Spring Pressure Connection Technology, aluminum conductors must first be cleaned with a blade and then immediately be inserted into the clamping units filled with “Alu-Plus” Contact Paste.

It is also possible to apply WAGO “Alu-Plus” additionally on the whole surface of the aluminum conductor before termination.

Please note that the nominal currents must be adapted to the reduced conductivity of the aluminum conductors:

2.5 mm² (14 AWG) = 16 A

4 mm² (12 AWG) = 22 A

Güvenlik bilgisi 1:

Diğer potansiyellerin parçalarına < 10mm mesafede 275V

Güvenlik bilgisi 2:

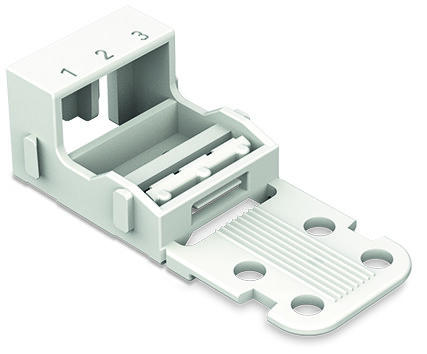

Sadece 773-331 Montaj Taşıyıcısı ile birlikte kullanılır.

| Nominal akım | 24A |

| Anma gerilimi EN (Ex e II) | 550V |

| Bağlantı teknolojisi | PUSH WIRE® |

| Actuation type | Push-in |

| Connectable conductor materials | Copper Aluminum |

| Tek damarlı boylar | 0,75 … 2,5 mm² / 18 … 14 AWG |

| Sıyırma uzunluğu | 12 mm / 0.47 inch |

| Toplam bağlantı noktası sayısı | 8 |

| Toplam potansiyel sayısı | 1 |

| Kablolama tipi | Yandan girişli kablolama |

| Width | 24 mm / 0.945 inch |

| Height | 13,1 mm / 0.516 inch |

| Depth | 19,5 mm / 0.768 inch |

| Renk | açık gri |

| Cover color | light gray |

| UL 94´e göre tutuşabilirlik değeri | V2 |

| Yangın yükü | 0,101MJ |

| Ağırlık | 4,7 |

| Surrounding air (operating) temperature | 60 °C |

| Continuous operating temperature | 105 °C |

| Product Group | 7 (Push Wire Conn.) |

| SAP´den ambalaj tipi | BOX |

| Country of origin | DE |

| GTIN | 4044918764865 |

| Customs Tariff No. | 85369010000 |

All of our products ensure maximum reliability even in challenging working conditions and help your business operations run smoothly. The products we offer in industrial automation, energy management, cabling solutions, and many other areas adapt flexibly to the needs of different sectors.

Additionally, our products are manufactured using only high-quality materials and comply with international standards. Through the solutions we provide, we enable our customers to increase operational efficiency and optimize costs. Our company closely follows technological advancements and continuously offers innovative products to help our customers gain a competitive advantage.

On each of our product pages, you can find comprehensive information about technical details, areas of use, and product features. You can explore all the products you need to strengthen your industrial processes on our website and enjoy a seamless purchasing experience.

Similar Products

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.