Eaton : XNH00-S160

183033 XNH00-S160

XNH00-S160 /183033

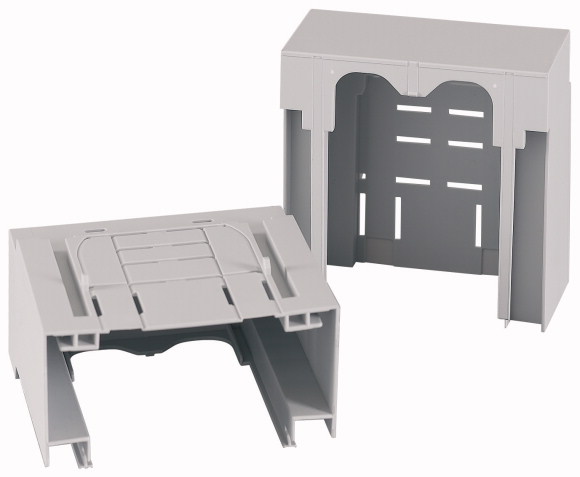

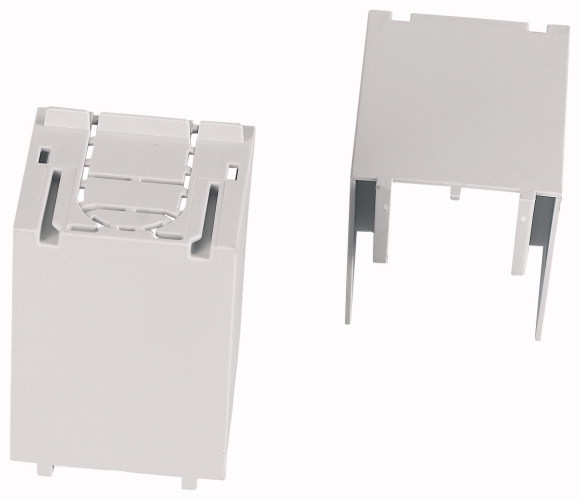

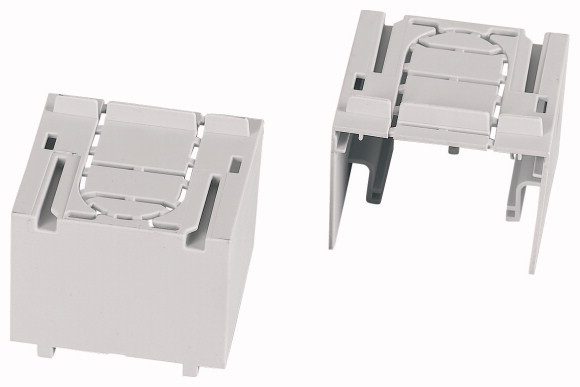

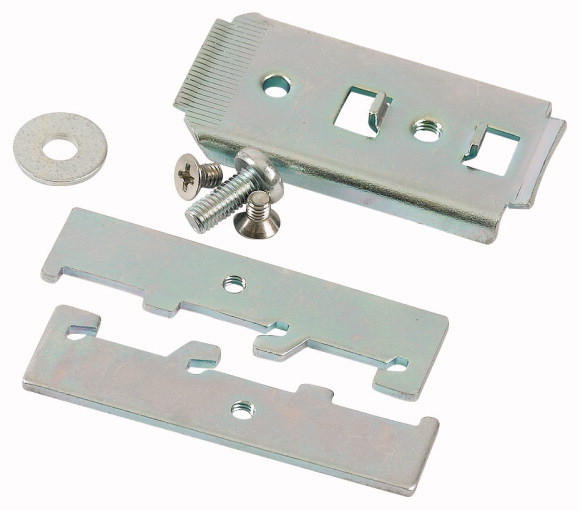

NH fuse-switch 3p flange connection M8 max. 95 mm²; busbar 60 mm; NH000 & NH00NH fuse switch-disconnector 3 pole with M8 flat terminal max. 95 mm²; busbar 60 mm; for NH000 & NH00 fuse-links; optionally lockable with XNH-XLOCK and padlock; upper/lower cable connection can be changed in seconds.

NH fuse-switch 3p flange connection M8 max. 95 mm²; busbar 60 mm; NH000 & NH00

NH fuse switch-disconnector 3 pole with M8 flat terminal max. 95 mm²; busbar 60 mm; for NH000 & NH00 fuse-links; optionally lockable with XNH-XLOCK and padlock; upper/lower cable connection can be changed in seconds.

| Basic function | Basic device |

| Number of poles | 3 pole |

| Mounting type | Busbars of 60 mm |

| Size | 00 |

| Type of connection | Flat connection |

| Rated operational current [Ie] | 160 A |

| Front degree of protection (XNH installed) | IP20 (Operating status) IP2XC (Contact protection) IP10 (Handle cover open) |

| Rated operational voltage [Ue ] | 690 V AC |

| Rated operational voltage [Ue] | 440 V DC |

| Rated conditional short-circuit current | 120 (500 V) 100 (690 V) kA |

| Flammability characteristics | Self-extinguishing as per UL 94 |

| Description | Current paths of electrolytic copper, silver-plated Cable connection optionally at the top or bottom |

| Successor to | 149418 |

| Standards | IEC/EN 60947-3 |

| Rated operational voltage [Ue ] | 690 V AC |

| Rated operational voltage [Ue] | 440 V DC |

| Rated operational current [Ie] | 160 A |

| Rated frequency [f] | 40 - 60 Hz |

| Rated insulation voltage [Ui] | 800 V AC |

| Total heat dissipation at Ith (without fuses) [Pv] | 14 W |

| Heat dissipation at 80% (without fuses) [Pv] | 9 W |

| Rated impulse withstand voltage [Uimp] | 8 kV |

| Utilization category AC-23B >Rated operating voltage [Ue] |

400 V AC |

| Utilization category AC-23B >Rated operating current [Ie] |

160 A |

| Utilization category AC22B >Rated operating voltage [Ue] |

500 V AC |

| Utilization category AC22B >Rated operating current [Ie] |

160 A |

| Utilization category AC-21B >Rated operating voltage [Ue] |

690 V AC |

| Utilization category AC-21B >Rated operating current [Ie] |

160 A |

| Utilization category

DC-22B >Rated operating voltage [Ue] |

250 V DC |

| Utilization category

DC-22B >Rated operating current [Ie] |

160 A |

| Utilization category DC21B >Rated operating voltage [Ue] |

440 V DC |

| Utilization category DC21B >Rated operating current [Ie] |

160 A |

| Rated conditional short-circuit current | 120 (500 V) 100 (690 V) kA |

| Rated short-time withstand current [Icw] | 7 kA |

| Max. fuse >Size according to DIN VDE 0636-2 |

000 / 00 |

| Max. fuse >Max. permitted power loss per fuse link [Pv] |

12 W |

| Lifespan, electrical [Operations] | 300 |

| Front degree of protection (XNH installed) | IP20 (Operating status) IP2XC (Contact protection) IP10 (Handle cover open) |

| Ambient temperature | -25 - +55 °C |

| Rated operating mode | Permanent operation |

| Activation | Dependent manual activation |

| Mounting position | Vertical, horizontal |

| Altitude | Max. 2000 m |

| Overvoltage category/pollution degree | III/3 |

| RoHS (in accordance with Directive 2002/95/EC of the European Parliament and Council) | Yes |

| Direction of incoming supply | as required (FLEX System) |

| Lockable | Yes, optional |

| Sealable | Yes, Standard |

| Material characteristics >Material |

Polyamide |

| Material characteristics >Colour |

Grey |

| Flammability characteristics | Self-extinguishing as per UL 94 |

| Halogen-free | Yes |

| Voltage test | Yes, sliding inspection windows |

| Lifespan, mechanical [Operations] | 1400 |

| Track resistance | CTI 600 |

| Heat deflection temperature | 125 °C |

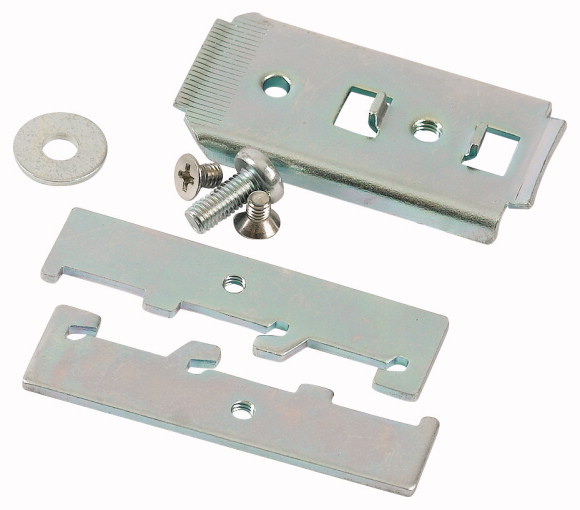

| Flange connection >Bolt diameter |

M8 |

| Flange connection >Cable lug max. width |

25 mm |

| Flange connection >Flat busbar |

20 x 10 mm |

| Box terminal >Stranded |

1,5 - 95 Cu mm2 |

| Box terminal >Copper strip [Number of segments x width x thickness] |

9 x 9 x 0,8 mm |

| Box terminal >Stranded |

1,5 - 50 Cu mm2 |

| Box terminal >Copper band [Number of segments x width x thickness ] |

6 x 9 x 0,8 mm |

| Clamp-type terminal >Stranded |

10 - 70 Cu/Al mm2 |

| Double clamp-type terminal >Stranded |

- mm2 |

| Rated operational current for specified heat dissipation [In] | 160 A |

| Heat dissipation per pole, current-dependent [Pvid] | 4.7 W |

| Equipment heat dissipation, current-dependent [Pvid] | 14 W |

| 10.2 Strength of materials and parts >10.2.2 Corrosion resistance |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.1 Verification of thermal stability of enclosures |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.2 Verification of resistance of insulating materials to normal heat |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.4 Resistance to ultra-violet (UV) radiation |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.5 Lifting |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.2 Strength of materials and parts >10.2.6 Mechanical impact |

Does not apply, since the entire switchgear needs to be evaluated. |

| 10.2 Strength of materials and parts >10.2.7 Inscriptions |

Meets the product standard´s requirements. |

| 10.3 Degree of protection of ASSEMBLIES | Does not apply, since the entire switchgear needs to be evaluated. |

| 10.4 Clearances and creepage distances | Is the panel builder´s responsibility. |

| 10.5 Protection against electric shock | Does not apply, since the entire switchgear needs to be evaluated. |

| 10.6 Incorporation of switching devices and components | Does not apply, since the entire switchgear needs to be evaluated. |

| 10.7 Internal electrical circuits and connections | Is the panel builder´s responsibility. |

| 10.8 Connections for external conductors | Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.2 Power-frequency electric strength |

Ui = 800 V AC |

| 10.9 Insulation properties >10.9.3 Impulse withstand voltage |

Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.4 Testing of enclosures made of insulating material |

Is the panel builder´s responsibility. |

| 10.10 Temperature rise | The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| 10.11 Short-circuit rating | Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| 10.12 Electromagnetic compatibility | Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| 10.13 Mechanical function | The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| Version as main switch | No |

| Version as safety switch | No |

| Max. rated operation voltage Ue AC | 690 V |

| Rated permanent current Iu | 160 A |

| Rated operation power at AC-23, 400 V | 0 kW |

| Conditioned rated short-circuit current Iq | 120 kA |

| Rated short-time withstand current lcw | 7 kA |

| Suitable for fuses | NH00 |

| Number of poles | 3 |

| With error protection | No |

| Type of electrical connection of main circuit | Screw connection |

| Cable entry | Other |

| Equipped with connectors | No |

| Suitable for ground mounting | No |

| Suitable for front mounting 4-hole | No |

| Suitable for busbar mounting | Yes |

| Type of control element | Cover grip |

| Position control element | Front side |

| Motor drive optional | No |

| Motor drive integrated | No |

| Version as emergency stop installation | No |

| Degree of protection (IP), front side | Other |

All of our products ensure maximum reliability even in challenging working conditions and help your business operations run smoothly. The products we offer in industrial automation, energy management, cabling solutions, and many other areas adapt flexibly to the needs of different sectors.

Additionally, our products are manufactured using only high-quality materials and comply with international standards. Through the solutions we provide, we enable our customers to increase operational efficiency and optimize costs. Our company closely follows technological advancements and continuously offers innovative products to help our customers gain a competitive advantage.

On each of our product pages, you can find comprehensive information about technical details, areas of use, and product features. You can explore all the products you need to strengthen your industrial processes on our website and enjoy a seamless purchasing experience.

Similar Products

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.