Eaton : KLV-PW-48-1PXL-1SPD-2PXF-16PLI

194711 KLV-PW-48-1PXL-1SPD-2PXF-16PLI

KLV-PW-48-1PXL-1SPD-2PXF-16PLI /Y7-194711

Assembled compact distribution board, 4-rows, flush sheet steel doorAssembled prewired and tested small distribution board KLV, with 1 x PXL circuit-breaker; 1 x SPCT2 TVSS; 2 x PXF residual current circuit-breaker; 16 x PLI circuit-breaker; universal plug-in terminal technology for all outgoing circuits; protection class II, front cover sealable; door turn-lock optionally interchangeable with safety lock mechanism; extensive range of accessories; level 3D plaster compensation for fast and clean assembly; including wall anchor standards: Combination in accordance with IEC/EN 60670-24, enclosure in accordance with DIN 43871, IEC/EN 62208, EN61439-3. The enclosure is suitable for cavity wall assembly. For cavity wall assembly, the cavity wall anchor type: HWS-KLV, article:178941 must be ordered separately; this is not included in the equipment supplied.

Assembled compact distribution board, 4-rows, flush sheet steel door

Assembled prewired and tested small distribution board KLV, with 1 x PXL circuit-breaker; 1 x SPCT2 TVSS; 2 x PXF residual current circuit-breaker; 16 x PLI circuit-breaker; universal plug-in terminal technology for all outgoing circuits; protection class II, front cover sealable; door turn-lock optionally interchangeable with safety lock mechanism; extensive range of accessories; level 3D plaster compensation for fast and clean assembly; including wall anchor standards: Combination in accordance with IEC/EN 60670-24, enclosure in accordance with DIN 43871, IEC/EN 62208, EN61439-3. The enclosure is suitable for cavity wall assembly. For cavity wall assembly, the cavity wall anchor type: HWS-KLV, article:178941 must be ordered separately; this is not included in the equipment supplied.

| Basic function | Basic device |

| Product function | Installation distribution boards |

| Product range | KLV DBO |

| Design | Hollow wall Flush mounted |

| Installation site | Indoor |

| Type of installation | Hollow-wall mounting and flush mounting |

| Door/Flap | White |

| Degree of Protection | IP30 |

| Colour | White |

| Module rack | Rail-frame |

| Shroud for protection against accidental contact | Plastic |

| Rows [Count] | 4 |

| Module units per row | 12 |

| Description | IP30 Protection Class II Plastic enclosure with sheet steel door, white (RAL 9016) |

| Cable entries | Cable entries on top and bottom, side, back plate |

| PE and N terminals design | Screw terminals + Plug-in terminals |

| PE and N terminals [Number x cross-sectional area] | PE: 4 x (2.5 - 25) + 28 x (0.5 - 4) N: 4 x (2.5 - 25) + 28 x (0.5 - 4) mm2 |

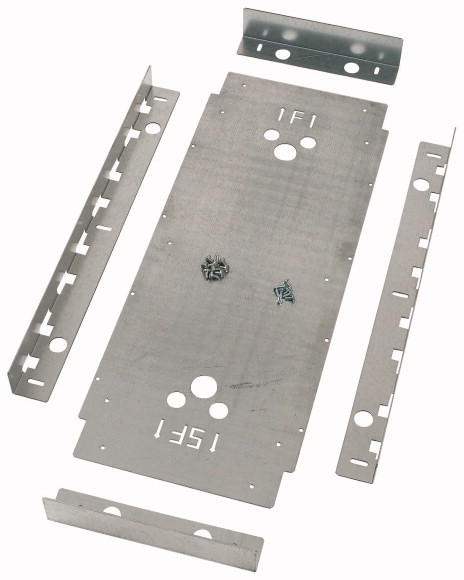

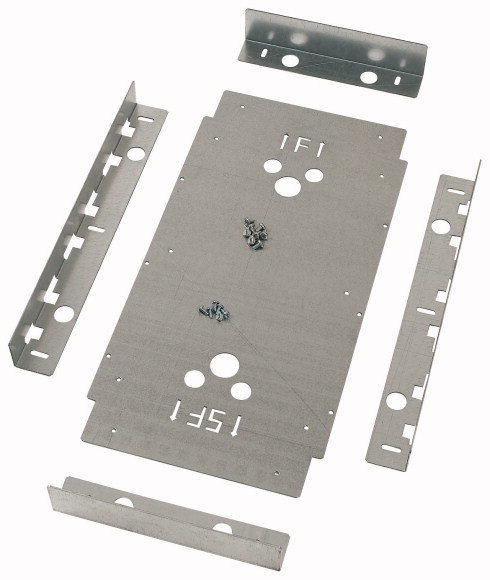

| Equipment supplied | Wall trough Door/Frame Device support rails Front cover Neutral and protective conductor terminals with KSK plug-in terminal technology Spirit level for leveling 3D adjustment element for mounting designed to adjust the mounting depth by up to 18 mm Cable retainer Nail lugs Installation instructions Imprintable sheet 1 Miniature circuit breaker PXL-C40/3 2 residual current circuit-breake PXF-40/4/003-A 16 Miniature circuit breaker PLI-B16/1 1 Surge protective device SPCT2-335-3+NPE Empty section cover Wired and tested in conformity with EN 61439-3 |

| Standards | IEC/EN 62208, IEC/EN 60670-24 |

| RoHS (in accordance with Directive 2002/95/EC of the European Parliament and Council) | conform |

| Ambient temperature | -5 - +40 °C |

| Degree of Protection | IP30 |

| Protection class | II (totally insulated) |

| Rated operational voltage [Ue] | 400 V AC |

| Rated frequency [f] | 50 Hz |

| Material | Polystyren (plastic) Sheet steel, powder-coated |

| Colour | white (RAL 9016) |

| Mechanical >Impact resistance |

IK05 |

| Heat dissipation, at an ambient temperature of 35°C, delta T: 20 degrees in top of the enclosure, calculated as per IEC 60890

>Individual enclosure, flush mounting [PV] |

45 W |

| Heat dissipation, at an ambient temperature of 35°C, delta T: 35 degrees in top of the enclosure, calculated as per IEC 60890

>Individual enclosure, flush mounting [PV] |

56 W |

| 10.2 Strength of materials and parts >10.2.2 Corrosion resistance |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.1 Verification of thermal stability of enclosures |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.2 Verification of resistance of insulating materials to normal heat |

Meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

850 °C; meets the product standard´s requirements. |

| 10.2 Strength of materials and parts >10.2.4 Resistance to ultra-violet (UV) radiation |

Not relevant to indoor installations. |

| 10.2 Strength of materials and parts >10.2.5 Lifting |

Does not apply to enclosures without lifting aids. |

| 10.2 Strength of materials and parts >10.2.6 Mechanical impact |

IK05 |

| 10.2 Strength of materials and parts >10.2.7 Inscriptions |

Meets the product standard´s requirements. |

| 10.3 Degree of protection of ASSEMBLIES | IP30 |

| 10.4 Clearances and creepage distances | Is the panel builder´s responsibility. |

| 10.5 Protection against electric shock | Protection class 2, therefore not applicable. |

| 10.6 Incorporation of switching devices and components | Is the panel builder´s responsibility. |

| 10.7 Internal electrical circuits and connections | Is the panel builder´s responsibility. |

| 10.8 Connections for external conductors | Is the panel builder´s responsibility. |

| 10.9 Insulation properties >10.9.2 Power-frequency electric strength |

Ui = 400 V AC |

| 10.9 Insulation properties >10.9.3 Impulse withstand voltage |

4 kV |

| 10.9 Insulation properties >10.9.4 Testing of enclosures made of insulating material |

Meets the product standard´s requirements. |

| 10.10 Temperature rise | The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| 10.11 Short-circuit rating | Is the panel builder´s responsibility. |

| 10.12 Electromagnetic compatibility | Is the panel builder´s responsibility. |

| 10.13 Mechanical function | The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| Mounting method | Flush mounted (plaster) |

| Number of phases | 3 |

| Protection | Miniature- / earth leakage circuit breaker |

| Total number of groups | 0 |

| Number of direct groups | 2 |

| Number of light groups | 0 |

| Number of groups behind earth leakage switch | 2 |

| Number of earth leakage circuit breakers | 0 |

| Number of earth leakage switches 30 mA | 2 |

| Number of earth leakage switches 300 mA | 0 |

| Number of poles main switch | 3 |

| Main switch rated current | 32 A |

| Cooker group | None |

| Cooker group suitable as power current group | No |

| With socket outlet | No |

| With bell transformer | No |

| Over voltage protection | Yes |

| Material housing | Plastic |

| Degree of protection (IP) | IP30 |

| Height | 714 mm |

| Width | 359 mm |

| Width in number of modular spacings | 12 |

| Depth | 96.5 mm |

| Built-in depth | 0 - 0 mm |

| Extension possible | No |

| With transparent cover | No |

| Lockable | No |

All of our products ensure maximum reliability even in challenging working conditions and help your business operations run smoothly. The products we offer in industrial automation, energy management, cabling solutions, and many other areas adapt flexibly to the needs of different sectors.

Additionally, our products are manufactured using only high-quality materials and comply with international standards. Through the solutions we provide, we enable our customers to increase operational efficiency and optimize costs. Our company closely follows technological advancements and continuously offers innovative products to help our customers gain a competitive advantage.

On each of our product pages, you can find comprehensive information about technical details, areas of use, and product features. You can explore all the products you need to strengthen your industrial processes on our website and enjoy a seamless purchasing experience.

Similar Products

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.