Eaton : KLV-24UPP-F

178800 KLV-24UPP-F

KLV-24UPP-F /178800

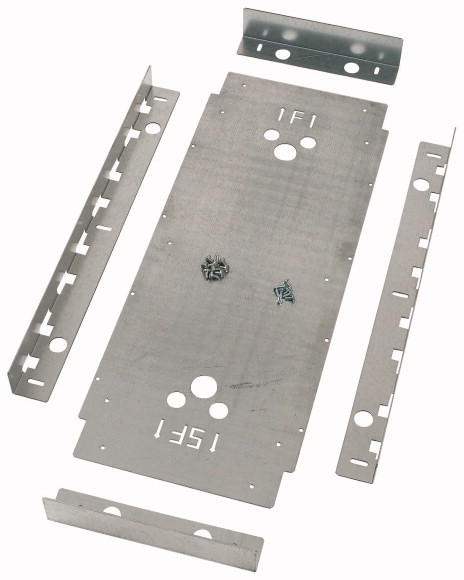

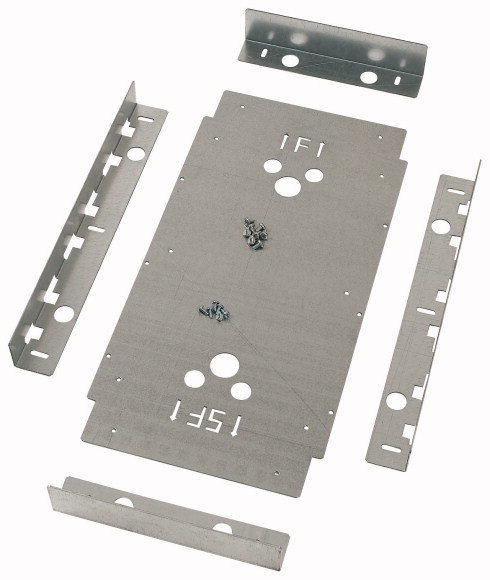

Compact distribution board-flush mounting; 2-rows; flush sheet steel doorSecond generation KLV flush mounting compact distribution boards, protection Class II, plastic enclosure with sheet steel door, front cover, sealable and laser-inscribed in accordance with IEC/EN 60670-24, plus 2-space-unit reserve per row, marking slot in wall box, slim door frame design, rugged door cam lock, optionally replaceable with safety interlock, cable retainer for neat wiring, optionally available in form of delivery for projects, optional door with frame with requested RAL color, comprehensive range of accessories, equipment supplied: enclosure, device carrier, front cover, neutral and protective conductor terminals with KSK plug-in terminal technology, spirit level for leveling, 3D adjustment element for mounting designed to adjust the mounting depth by up to 18 mm, cable retainer, nail lugs, installation instructions, imprintable sheet, special packaging designed to meet real-life application requirements. Standards: In accordance with IEC/EN 60670-24, DIN 43871, IEC/EN 62208 and, accordingly, approved for distribution boards as defined in IEC/EN 61439-3.

Compact distribution board-flush mounting; 2-rows; flush sheet steel door

Second generation KLV flush mounting compact distribution boards, protection Class II, plastic enclosure with sheet steel door, front cover, sealable and laser-inscribed in accordance with IEC/EN 60670-24, plus 2-space-unit reserve per row, marking slot in wall box, slim door frame design, rugged door cam lock, optionally replaceable with safety interlock, cable retainer for neat wiring, optionally available in form of delivery for projects, optional door with frame with requested RAL color, comprehensive range of accessories, equipment supplied: enclosure, device carrier, front cover, neutral and protective conductor terminals with KSK plug-in terminal technology, spirit level for leveling, 3D adjustment element for mounting designed to adjust the mounting depth by up to 18 mm, cable retainer, nail lugs, installation instructions, imprintable sheet, special packaging designed to meet real-life application requirements. Standards: In accordance with IEC/EN 60670-24, DIN 43871, IEC/EN 62208 and, accordingly, approved for distribution boards as defined in IEC/EN 61439-3.

All of our products ensure maximum reliability even in challenging working conditions and help your business operations run smoothly. The products we offer in industrial automation, energy management, cabling solutions, and many other areas adapt flexibly to the needs of different sectors.

Additionally, our products are manufactured using only high-quality materials and comply with international standards. Through the solutions we provide, we enable our customers to increase operational efficiency and optimize costs. Our company closely follows technological advancements and continuously offers innovative products to help our customers gain a competitive advantage.

On each of our product pages, you can find comprehensive information about technical details, areas of use, and product features. You can explore all the products you need to strengthen your industrial processes on our website and enjoy a seamless purchasing experience.

Similar Products

Can't find the product you're looking for?

LET US HELP YOU

Can't Find the Product You're Looking For? Let Us Know, and We'll Source It for You!

Are you searching for products not listed on our website or out of stock? Let us know your requirements, and our expert team will contact you as soon as possible to find the most suitable solution for you.