| Product range |

CI-K small enclosures |

| Basic function |

Basic enclosures |

| Product function |

Empty enclosure CI-K2 |

| Single unit/Complete unit |

Single unit |

| Degree of Protection |

IP30 |

| Degree of Protection |

IP20

IP30 |

| Material |

Glass-fibre reinforced polycarbonate |

| Colour |

Enclosure base RAL 9005, black

Operator only RAL 7035, light gray |

| Description |

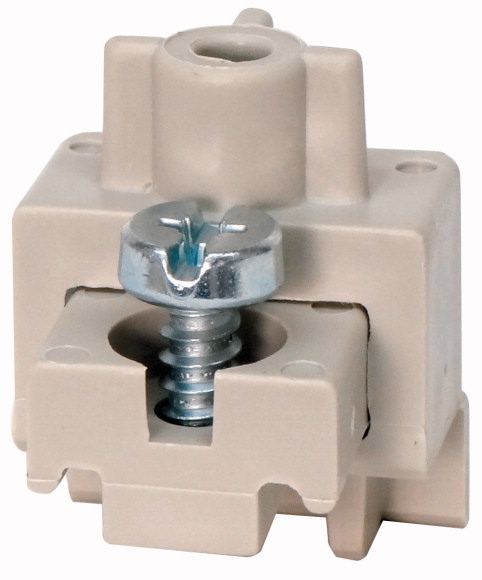

Metric cable entry knockouts top, bottom and in the back plate

Hard metric cable entry knockouts

Control cable entry

Lamp indicator L‐… can be mounted in base knock-out M20/M25

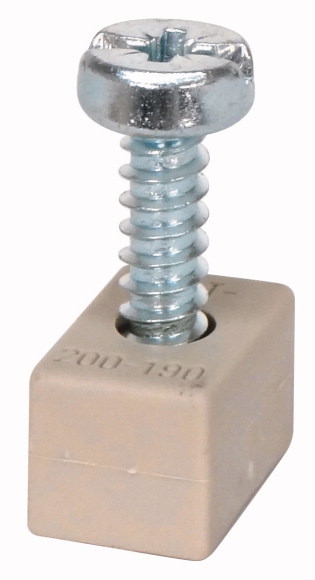

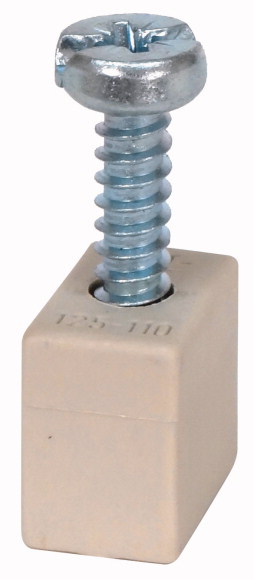

Standard cutout dimensions and mounting rail for devices requiring up to 4 space units

Close off of unused space units (max. 2) using VST1 blanking strips |

| Cable entry |

hard knockout version |

| Dimensions |

|

| Legend for the graphic |

Dimensions from top:

Mounting depth with mounting plate

Mounting depth for mounting rail 7.5 mm height

Mounting depth for mounting rail 15 mm height |

| Enclosure depth |

|

| Mounting depth for mounting rail 7.5 mm height |

46 mm |

| Features |

with cover cutout |

| Notes |

| M | q |

|

| Knockouts | Knockouts | | 2 X M25 or push-through membrane up to max. ⌀ 16 mm | 2 x M25 or push-through membrane up to a max. diameter of 16 mm and 1 push-through membrane up to a max. diameter of 8 mm | | | | | T | |

| | Back plate: | | | 2 x push-through membrane up to max. ⌀ 11mm | | | (not for CI-K2H) | |

|

| Notes |

Membrane grommets, cable glands Chapter 14, Accessories |

| Standards |

IEC/EN 60529

DIN EN 62208 |

| Climatic proofing |

Damp heat, constant, to IEC 60068-2-78

Damp heat, cyclic, to IEC 60068-2-30 |

| Ambient temperature |

-25 - +70

-25 - +40 (with push-through cable entry) °C |

| Degree of Protection |

IP30 |

Material

>Base |

Glass-fibre reinforced polycarbonate |

Material

>Cover |

Glass-fibre reinforced polycarbonate |

| Surface treatment |

Resistant to corrosion |

Colour

>Base |

RAL 9005, black (matt) |

Colour

>Housing body |

Enclosure cover RAL 7035, light grey (matt) |

Electrical

>Track resistance |

CTI 175 (base, to IEC 60112)

CTI 175 (cover, to IEC 60112) |

Electrical

>Surface resistance to IEC 60093 |

1 Ω x 1013

|

Electrical

>Dielectric strength to IEC 60243-1 |

30 kV/mm |

Thermal

>Temperature resistant |

-40 °C - 120 °C (enclosure)

-40 °C - +80 °C (gasket) |

Mechanical

>Impact resistance |

IK06 according to EN 50102 |

Mechanical

>max. assembly weights

>Mounting plate |

0.7 kg |

Mechanical

>max. assembly weights

>Mounting rail |

0.7 kg |

Chemical resistance

>Chemical resistant |

Base, Cover

Resistant against: Acids < 10 %, mineral oil, alcohol, gasoline, greases, salt solutions

Partly resistant to: Acids > 10 %, alcohol

Not resistant to: alkalis, benzene

Push-through membrane (CI-K1/CI-K2) and sealing material

Resistant against: Acids < 10 %, alkalis, benzene, salt solutions

Partly resistant to: Acids > 10 %, greases, benzene

Not resistant to: Mineral oil, benzene |

Atmospheric

>Saline spray |

IEC 60068-2-11 |

Atmospheric

>UV resistance |

Beneath protective shield |

Atmospheric

>Water consumption to DIN EN ISO 62 |

0.29 % |

Flammability characteristics

>Glow wire test

>Flammability characteristics |

960 °C/1mm thickness (base, cover; glow wire to VDE 0471 Part 2)

650 °C/1mm thick (push-through membrane and seal material) to VDE 0471 Part 2) |

Flammability characteristics

>Glow wire test

>to UL 94 |

VO/1.5 mm thickness |

Flammability characteristics

>Glow wire test

>to UL 94 |

HB |

Flammability characteristics

>Halogen free |

Yes |

| Rated operational current for specified heat dissipation [In] |

0 A |

| Heat dissipation per pole, current-dependent [Pvid] |

0 W |

| Equipment heat dissipation, current-dependent [Pvid] |

0 W |

| Static heat dissipation, non-current-dependent [Pvs] |

0 W |

| Heat dissipation capacity [Pdiss] |

10 W |

| Operating ambient temperature min. |

-25 °C |

| Operating ambient temperature max. |

+70 °C |

| Degree of Protection |

IP30 |

| Flammability characteristics |

960 °C/1mm thickness (base, cover; glow wire to VDE 0471 Part 2)

650 °C/1mm thick (push-through membrane and seal material) to VDE 0471 Part 2) |

| Track resistance |

CTI 175 (base, to IEC 60112)

CTI 175 (cover, to IEC 60112) |

| Surface treatment |

Resistant to corrosion |

| Impact resistance |

IK06 according to EN 50102 |

| Temperature resistant |

-40 °C - 120 °C (enclosure)

-40 °C - +80 °C (gasket) |

| UV resistance |

Beneath protective shield |

10.2 Strength of materials and parts

>10.2.2 Corrosion resistance |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.3.1 Verification of thermal stability of enclosures |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.3.2 Verification of resistance of insulating materials to normal heat |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.3.3 Verification of resistance of insulating materials to abnormal heat and fire due to internal electric effects |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.4 Resistance to ultra-violet (UV) radiation |

Please enquire |

10.2 Strength of materials and parts

>10.2.5 Lifting |

Not applicable. |

10.2 Strength of materials and parts

>10.2.6 Mechanical impact |

Meets the product standard´s requirements. |

10.2 Strength of materials and parts

>10.2.7 Inscriptions |

Meets the product standard´s requirements. |

| 10.3 Degree of protection of ASSEMBLIES |

Meets the product standard´s requirements. |

| 10.4 Clearances and creepage distances |

Meets the product standard´s requirements. |

| 10.5 Protection against electric shock |

Is the panel builder´s responsibility. |

| 10.6 Incorporation of switching devices and components |

Is the panel builder´s responsibility. |

| 10.7 Internal electrical circuits and connections |

Is the panel builder´s responsibility. |

| 10.8 Connections for external conductors |

Is the panel builder´s responsibility. |

10.9 Insulation properties

>10.9.2 Power-frequency electric strength |

Is the panel builder´s responsibility. |

10.9 Insulation properties

>10.9.3 Impulse withstand voltage |

Is the panel builder´s responsibility. |

10.9 Insulation properties

>10.9.4 Testing of enclosures made of insulating material |

Meets the product standard´s requirements. |

| 10.10 Temperature rise |

The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices. |

| 10.11 Short-circuit rating |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| 10.12 Electromagnetic compatibility |

Is the panel builder´s responsibility. The specifications for the switchgear must be observed. |

| 10.13 Mechanical function |

The device meets the requirements, provided the information in the instruction leaflet (IL) is observed. |

| Material housing |

Plastic |

| Width |

100 mm |

| Height |

181 mm |

| Depth |

80 mm |

| With transparent cover |

No |

| Suitable for emergency stop |

No |

| Model |

Surface mounting |

| Degree of protection (IP) |

IP30 |

| Degree of protection (NEMA) |

Other |